Cotton Crack Seed Separator in Maharashtra

Introduction

At Padsons Industries, we specialize in crafting user-friendly manual and semi-automatic farm machinery. With a focus on simplicity and effectiveness, our equipment is designed to make farming tasks more efficient and accessible for all. Our range includes a variety of tools that cater to the diverse needs of farmers. From easy-to-use plows to hassle-free seeders, we take pride in creating machinery that simplifies the farming process. With decades of experience in the industry, we understand the challenges faced by modern-day farmers. That’s why we’re dedicated to providing practical solutions that enhance productivity and yield. Trust Padsons Industries to be your reliable partner in agriculture.

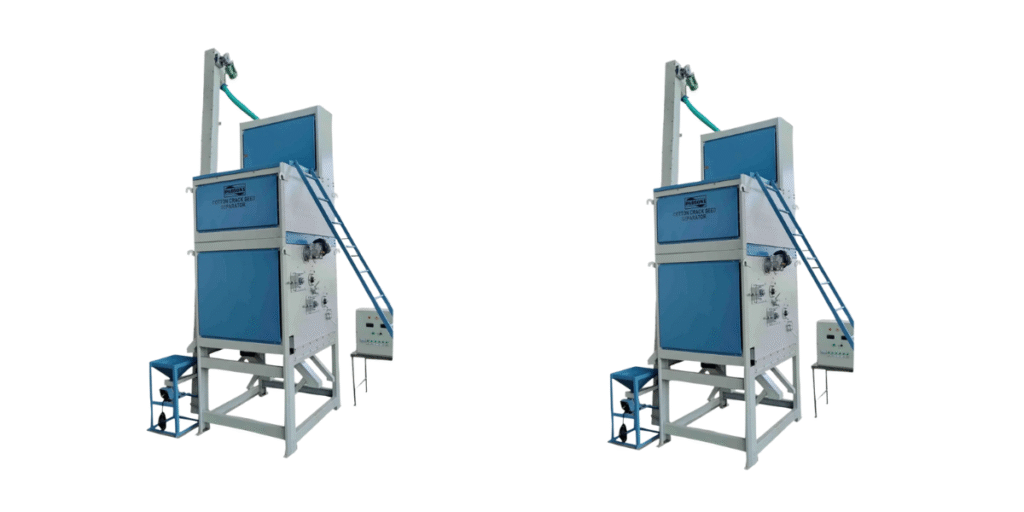

One of Maharashtra’s most important crops, cotton makes a substantial contribution to the state’s agricultural economy. But processing cotton has its own set of difficulties, particularly when it comes to effectively extracting cotton fibers from seeds. Cotton Crack Seed Separators are essential in this situation since they increase output and guarantee superior cotton processing. At Padsons Industries, we offer premium cotton seed separation equipment made to satisfy the unique requirements of Maharashtra’s farmers and cotton processing facilities. We are the best Cotton Crack Seed Separator Manufacturer.

What is a Cotton Crack Seed Separator

After harvesting, cotton seeds are separated from cotton fibers using a machine called a Cotton Crack Seed Separator. Conventional seed separation techniques were time-consuming, labor-intensive, and frequently resulted in fiber damage. In order to ensure that seeds are separated neatly without sacrificing the quality of cotton fibers, modern machines, such as those provided by Padsons Industries, are designed to be effective, accurate, and long-lasting. The textile, seed processing, and cotton ginning industries all make extensive use of these devices. Farmers and companies can save time, cut labor expenses, and boost overall productivity by automating the separation process. We are the best Cotton Crack Seed Separator Supplier.

Why Choose Padsons Industries

- Uncompromising Quality Commitment Every Padsons Cotton Crack Seed Separator reflects our steadfast dedication to quality. We implement stringent quality checks on all raw materials and maintain a zero-tolerance approach to deviations from our high standards . Our manufacturing facilities in Akola are equipped with world-class testing facilities, ensuring that every machine performs reliably under demanding industrial conditions.

- Decades of Industry Expertise With a legacy dating back to Padsons Industries possesses deep-rooted knowledge of agricultural processing challenges and solutions. Our company originated with the Padgilwar Group, pioneering advancements in farm machinery that have stood the test of time . This extensive experience translates into equipment that genuinely understands and addresses the real-world problems faced by cotton processors across Maharashtra.

- Customized Solutions for Diverse Needs We recognize that every processing operation has unique requirements. Padsons offers a comprehensive range of separators including standard, high-capacity, and compact models to suit facilities of all sizes . Our technical team works closely with clients to develop tailored solutions that address specific processing challenges and production goals.

- Exceptional After-Sales Support For Padsons Industries, the sale of a machine marks the beginning of an enduring relationship with our clients . We provide comprehensive after-sales service including technical assistance, spare parts availability, and operational guidance to ensure your processing line runs smoothly year after year. Our service network extends across Maharashtra and throughout India.

- Compromised Fiber Quality: Contaminated lint with seed fragments loses market value and fails to meet quality standards demanded by textile mills and export markets. The presence of these impurities can downgrade your entire batch.

- Reduced Oil Extraction Efficiency: For cottonseed oil extraction plants, clean seeds are essential for maximizing oil recovery. Cracked seeds mixed with lint reduce the efficiency of oil presses and can increase impurities in the final crude oil product.

- Operational Inefficiencies: Manual separation methods require significant labor and still deliver inconsistent results. This traditional approach is neither scalable nor cost-effective for modern processing facilities.

- Robust and Durable Construction: Recognizing the demanding environment of processing facilities, we build our separators using high-quality materials including stainless steel and robust mild steel. This ensures minimal wear and tear, lower maintenance costs, and a longer operational lifespan.

- High Capacity and Efficiency: Our machines are designed for large-scale applications, making them ideal for ginning mills and oil extraction plants across Maharashtra where processing efficiency directly impacts profitability.

Applications of Cotton Crack Seed Separator

1. Ginning Units

- In ginning units, cotton is processed to separate lint from seeds. Our machines ensure seeds are cracked efficiently and separated cleanly, allowing ginning units to maintain high throughput.

2. Oil Extraction Industries

- Cotton seeds are a primary source for cottonseed oil. Using a high-quality separator ensures that seeds are properly cracked and cleaned, resulting in better oil extraction and higher yield.

3. Seed Processing Units

- Seed quality is critical for future sowing. Cotton seed separators ensure that only healthy and clean seeds are used, improving germination rates and overall crop quality.

4. Fertilizer Production

- Cotton seed by-products such as cake and meal are widely used in fertilizer production. Proper seed separation ensures that these by-products are of high quality, enhancing their efficiency as organic fertilizers.

5. Animal Feed Industry

- Cottonseed meal and cake are also used as protein-rich animal feed. Effective separation ensures minimal contamination with fibers, making it safe and nutritious for livestock.

6. Cotton Ginning Units

- Ginning factories process large quantities of raw cotton. Cotton Crack Seed Separators streamline operations by efficiently separating seeds and lint, improving overall productivity.

7. Textile Industry

- The primary application of these machines is in the textile industry. After separating seeds from cotton, the clean lint can be processed into high-quality yarn and fabrics. Cities like Mumbai, Pune, and Nagpur have booming textile industries that benefit from efficient cotton seed separation.

Specifications Table of Cotton Crack Seed Separator

| Specification | Details |

|---|---|

| Material | Cotton Crack Seed Separator |

| Capacity | 500 kg/hour |

| Power Requirement | 5 HP Electric Motor |

| Material | Mild Steel & Stainless Steel |

| Dimensions (LxWxH) | 1500 x 800 x 1200 mm |

| Weight | 250 kg |

| Separation Efficiency | 95% |

| Operation Type | Manual / Electric |

| Maintenance | Low |

| Warranty | 1 Year |

Benefits of Cotton Crack Seed Separators

- Magnetic Separation Technology: Padsons’ separators incorporate dual magnetic rollers that effectively attract and remove metallic contaminants and iron powder used in the separation process. This system ensures that the finished product remains free from metallic impurities that could compromise quality.

- Gravity-Based Separation: Utilizing differences in weight and density, this method allows heavier whole seeds to separate from lighter cracked seed fragments and lint. The machine creates controlled air currents that carry away lighter materials while permitting denser seeds to follow their intended path.

- Sensor-Based Automation: Advanced sensor systems continuously monitor the operation, automatically stopping the machine if the iron powder buffer bin becomes empty. This intelligent feature prevents the system from running without essential separation materials, thereby maintaining consistent output quality.

- Self-Cleaning Mechanism: Padsons separators incorporate innovative self-cleaning functionality that eliminates the need for manual cleaning after each batch. This not only reduces labor requirements but also minimizes downtime between processing cycles, significantly enhancing overall operational efficiency.

- High Processing Capacity: With the ability to process approximately 1 ton of cotton seeds per hour, these machines enable large-scale operations to maintain consistent throughput without compromising on separation quality . This remarkable capacity ensures that processing facilities can keep pace with demanding production schedules, particularly during peak harvesting seasons when volumes are at their highest.

- Labor Optimization: By automating a process that was traditionally performed manually, Cotton Crack Seed Separators significantly reduce labor requirements. This automation not only lowers operational costs but also minimizes human error, ensuring consistent results regardless of workforce variations or skill levels.

- Continuous Operation: The sophisticated self-cleaning mechanism incorporated into Padsons separators eliminates the need for thorough cleaning between batches. This feature allows for nearly continuous operation, dramatically reducing downtime and maximizing productive hours throughout the workday.

- Unparalleled Separation Efficiency: Padsons Cotton Crack Seed Separators deliver an exceptional 95-98% separation rate, ensuring that cracked seed fragments are effectively removed from the production stream . This high level of precision directly translates to superior product purity that meets the most stringent quality standards.

- Enhanced Fiber Quality: By removing cracked seed fragments from cotton lint, the separator significantly improves the overall quality and market value of the fiber. This purity is particularly important for Maharashtrian cotton processors seeking to compete in premium markets where fiber quality commands price premiums.

- Optimized Oil Extraction: For cottonseed oil extraction facilities, the removal of cracked seeds and impurities results in higher oil recovery rates and improved crude oil quality. The clean seeds fed into extraction equipment enable more efficient processing and better final product quality.

Types of Cotton Crack Seed Separators

1. Manual Cotton Seed Separator

- Ideal for small-scale farmers, this type of separator is simple to operate, requires minimal maintenance, and is cost-effective. It is best suited for areas with low cotton yield or for farmers who process cotton occasionally.

2. Semi-Automatic Cotton Seed Separator

- This machine combines manual operation with mechanical efficiency. It is suitable for medium-scale operations and provides faster seed separation compared to manual methods.

3. Fully Automatic Cotton Seed Separator

- Designed for large-scale industrial operations, fully automatic separators provide the highest efficiency. They can process large volumes of cotton quickly, maintain uniform seed quality, and significantly reduce human effort.

4. Electric Cotton Seed Separators

- Electric separators are designed for medium to large-scale operations. They are powered by electricity, which increases processing speed and efficiency.

5. Automatic Cotton Seed Separators

- Automatic separators are fully mechanized and suitable for industrial-scale operations. They are equipped with advanced technology to separate seeds quickly and efficiently with minimal human intervention.

Conclusion

Efficient cotton seed separation is crucial for Maharashtra’s cotton industry, impacting both quality and profitability. A Cotton Crack Seed Separator in Maharashtra not only streamlines the process but also ensures that cotton seeds and fibers are ready for their respective uses.

Padsons Industries stands out as a leading provider of these machines, offering reliable, durable, and high-performance solutions. With a focus on quality, efficiency, and customer satisfaction, Padsons Industries has become the go-to choice for farmers, ginning mills, and textile units in Maharashtra. Investing in a quality separator from Padsons Industries ensures cleaner cotton, higher productivity, and better profitability—making it an essential tool for anyone involved in cotton processing.