Millet Processing Plant Supplier in Maharashtra

Introduction

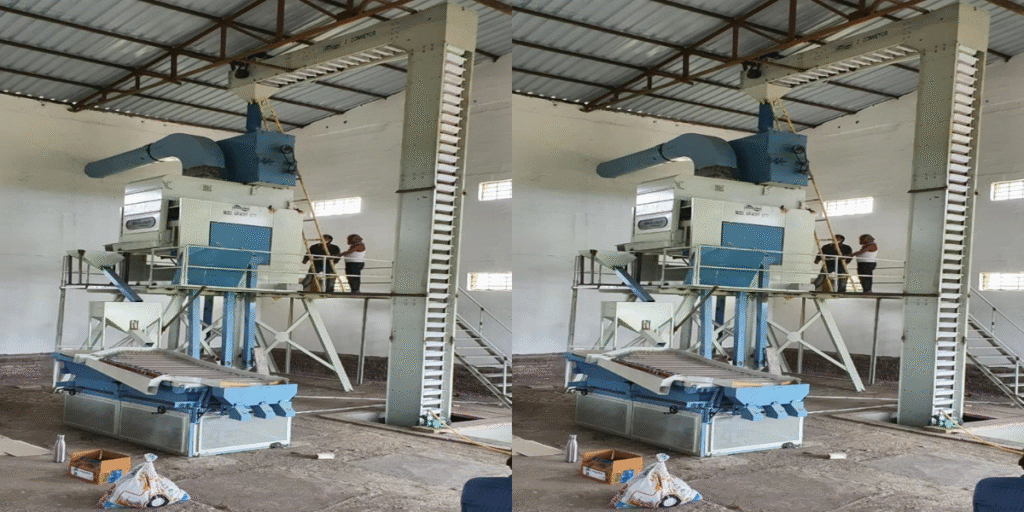

At Padsons Industries, we specialise in crafting user-friendly manual and semi-automatic farm machinery. With a focus on simplicity and effectiveness, our equipment is designed to make farming tasks more efficient and accessible for all. Our range includes a variety of tools that cater to the diverse needs of farmers. From easy-to-use ploughs to hassle-free seeders, we take pride in creating machinery that simplifies the farming process. With decades of experience in the industry, we understand the challenges faced by modern-day farmers. That’s why we’re dedicated to providing practical solutions that enhance productivity and yield. Trust Padsons Industries to be your reliable partner in agriculture.

Millets have gained prominence in India’s agricultural and nutritional landscape in recent years. Millets, including jowar, bajra, ragi, and foxtail millet,s are becoming increasingly popular both domestically and abroad due to their high nutritional profile, resilience to climate change, and economic viability. The requirement for effective processing systems that can manage high capacity without sacrificing quality is growing along with demand. This is where having a reliable Maharashtra supplier of millet processing plants becomes crucial. As a top producer and supplier of cutting-edge millet processing facilities in the area, Padsons Industries stands out for assisting farmers, business owners, and food corporations in modernising their processing operations. We are the best Millet Processing Plant Manufacturer.

Why Are Millet Processing Plant

One of India’s top states for millet production is Maharashtra. Commercial millet processing has increased due to factors like the government’s emphasis on nutrient-dense food security, growing retail demand, and the revival of traditional grains. Well-designed processing lines are necessary for important millet products such as millet flour (atta), flakes, ready-to-eat snacks, puffed millets, and malted grains. In Maharashtra, turn-key millet processing systems that offer high capacity, durability, and automation are becoming more and more sought after by investors, entrepreneurs, and current mill owners. Padsons Industries has established itself in this market. We are the best Millet Processing Plant Exporter.

Why Choose Padsons Industries

- Unmatched After-Sales Support: Padsons believes the partnership continues long after installation. They provide comprehensive support, including installation supervision, operator training, and readily available technical assistance and spare parts. This minimises downtime and protects your investment.

- Proven Experience and Recognition: With a history spanning over half a century, Padsons’ deep industry knowledge is reflected in its numerous accolades. These include the Rashtriya Udyog Ratna Award, the Maharashtra State Export Award, and recognition as the “Best Agro Processing Machines Manufacturer & Exporter” by the Government of Maharashtra. This award-winning track record is a testament to their reliability and commitment to excellence.

- End-to-End, Customer-Centric Partnership: Padsons distinguishes itself through a philosophy where “the selling of a machine is not the end, but the beginning of an enduring relation”. They provide complete turnkey solutions, managing everything from initial design and manufacturing to installation, commissioning, and operator training. Their dedication to after-sales service, including readily available spare parts and technical support, minimises downtime and protects your investment.

- Commitment to Quality and Innovation: As a certified company, Padsons embeds quality at every stage. They enforce a “zero tolerance” policy on raw materials, mandating stringent checks to ensure only the best components are used. Their innovative spirit is secured with several patents for agricultural machinery, demonstrating a continuous drive to improve and adapt to modern farming and processing needs.

- Scalable and Customised Designs: Understanding that one size does not fit all, Padsons offers remarkable flexibility. They provide solutions for every scale of operation, from semi-automatic units perfect for small enterprises or community processing to fully automated, high-capacity plants for large-scale industrial production. Their modular plant designs allow for future expansion with minimal disruption, ensuring your business can grow without outgrowing your processing facility.

- Comprehensive Product Range & Customisation: Padsons provides more than just a standalone machine; they offer complete, end-to-end solutions. Whether you are a small-scale entrepreneur or a large agro-industrial unit, they tailor plant capacity and automation levels from manual to PLC-controlled to fit your specific production goals and budget.

- Proven Legacy & Award-Winning Excellence: Founded in under the Padgilwar Group, Padsons has a deep-rooted understanding of farmers’ and processors’ needs. Their commitment to quality is recognised through multiple prestigious awards, including the Rashtriya Udyog Ratna Award and the Government of Maharashtra’s Best Agro Processing Machines Manufacturer & Exporter award.

- Complete, Scalable Solutions: Padsons offers fully automatic to semi-automatic plants tailored to any scale of operation—from a small entrepreneur starting a local brand to a large corporation meeting national demand. They provide full turnkey projects, managing everything from design and installation to commissioning and operator training.

- Deep Technical Mastery for a Complex Crop: Unlike wheat, millets demand specific processing techniques to preserve nutrients and ensure functionality in end products. Padsons’ plants are engineered to handle the delicate nature of various millets—from pearl millet to finger millet and foxtail millet, ensuring minimal grain breakage and maximum yield of high-quality flour, or polished grain.

Applications of Millet Processing Plants

1. Primary Cleaning & Pre‑Processing

- Millet processing plants begin with the removal of foreign matter, dirt, stones, dust, and plant residues. This is essential to meet quality and safety standards before millets enter further processing stages.

2. Dehusking & De‑Graining

- Efficient dehusking machines remove the outer hull of millets like pearl milletfinger millet, foxtail millet, kodo millet, little millet, barnyard millet, and proso millet, without damaging the kernels.

3. Polishing & Whitening

- Polished millets have improved taste, appearance, and shelf appeal, making them more desirable in retail markets and food product manufacturing.

4. Animal Feed

- Processed millet by-products are highly nutritious and used in animal feed. Hulling and polishing operations produce bran and husk, which can be efficiently utilised in livestock and poultry feed.

5. Cleaning and Sorting

- The first step in millet processing involves thorough cleaning and sorting. Our advanced cleaning machines remove impurities like stones, dust, husks, and other foreign materials, ensuring only high-quality millet is processed further.

6. De-husking and De-hulling

- Millets have a hard outer shell that needs to be removed before consumption. Our de-husking and de-hulling machines efficiently remove husks without damaging the grain, ensuring maximum yield and quality.

7. Packaging Solutions

- A critical step in modern food processing is hygienic and attractive packaging. Padsons Industries offers automatic packaging systems that ensure processed millets and millet flour are sealed safely, retaining freshness and quality for end consumers.

8. Grinding and Milling

- Once cleaned and de-husked, millets are milled into flour or meal. Our milling units are designed to produce fine and uniform millet flour, ideal for a variety of applications, including.

Table of Specifications Millet Processing Plant

| Specification | Details |

|---|---|

| Material | Millet Processing Plant |

| Supplier Location | Maharashtra (e.g., Pune / Mumbai / Nashik) |

| Plant Capacity Range | 500 kg/day – 5,000 kg/day |

| Millet Types Covered | Finger Millet (Ragi), Pearl Millet (Bajra), Little Millet, Foxtail Millet, etc. |

| Primary Equipment | Cleaner, De-stoner, Huller/De-huller, Separator, Polisher |

| Material of Construction | Mild Steel / Stainless Steel (food-grade) |

| Power Requirement | 10 HP – 50 HP (varies by capacity) |

| Control System | Semi‑automatic / Fully Automatic PLC Panel |

| Installation & Commissioning | Included (in Maharashtra) |

| Warranty | 12–24 months (varies by supplier) |

| After‑Sales Support | Spare parts, maintenance, training |

| Certifications | ISO / CE (if applicable) |

| Delivery Timeline | 4–8 weeks (typical) |

Benefits of Millet Processing Plant

- Maximised Efficiency and Profitability: Padsons’ machinery is designed with an emphasis on operational efficiency, reducing grain breakage during dehulling to maximise yield from your raw materials. Their energy-efficient designs help control electricity costs, directly impacting your profit margins.

- Unmatched Versatility and Scalability: Padsons offers tailored solutions for businesses of all scales. They provide flexible plant designs, from small, semi-automatic units perfect for community-level processors or startups to fully automated, high-capacity systems for large-scale industrial production, ensuring your investment grows with your business.

- Complete Business Support: The partnership with Padsons extends far beyond the initial sale. They offer comprehensive turnkey projects that handle everything from initial consultation and plant layout design to equipment installation, testing, and operator training. Their dedicated after-sales support, including readily available technical assistance and spare parts, minimises downtime and protects your investment.

- End-to-End Turnkey Solutions: Padsons provides comprehensive services from initial plant design and equipment manufacturing to installation, commissioning, and operator training. This holistic approach ensures a smooth, hassle-free setup.

- Scalability and Customisation: They offer solutions for every scale of operation, from small semi-automatic units ideal for startups and Farmer-Producer Organisations (FPOs) to fully automated, high-capacity plants for large-scale processors.

- Diverse Product Portfolio: Beyond millet-specific plants, their expertise extends to a full range of ancillary equipment essential for a processing unit, such as destoners, graders, elevators, and cleaners. This allows clients to source a fully integrated system from a single, reliable vendor.

- Superior After-Sales Support: Recognising that machinery is a long-term investment, Padsons emphasises strong after-sales service, including readily available spare parts and technical support, which minimises downtime and protects your investment.

- Enhanced Profitability: Advanced processing technology is designed to maximise grain yield and minimise breakage during dehusking, directly improving your bottom line.

- Comprehensive End-to-End Solutions Padsons doesn’t just sell machines; they deliver complete turnkey projects. From initial consultation and plant layout design to equipment installation, commissioning, and after-sales service, they guide you through every step, ensuring a seamless and efficient setup for your processing unit.

Types of Millet Processing Plants

1. Small-Scale Millet Processing Plant

- Ideal for startups or businesses with limited production needs, the small-scale plant is compact, cost-effective, and easy to operate. It includes essential equipment for cleaning, dehulling, and packaging. Despite its size, it ensures high-quality output and consistent performance.

2. Medium-Scale Millet Processing Plant

- Designed for medium-scale businesses or cooperative societies, this type of plant has higher processing capacity and automation features. It supports multiple types of millets, such as ragi, jowar, bajra, and foxtail millet, allowing producers to diversify their product range.

3. Specialty Millet Processing Plants

- Padsons Industries also offers specialized plants for processing particular millet varieties, such as finger millet (ragi) flour plants or barnyard millet processing units. These plants are optimized for high yield, quality consistency, and specific end-product requirements.

4. Large-Scale Millet Processing Plant

- Our large-scale millet processing plants are perfect for industrial use and large commercial production. These plants are fully automated, designed to handle high-capacity operations, and equipped with multiple processing stages, including.

4. Customised Millet Processing Plant

- Padsons Industries also offers customised millet processing plants based on client-specific needs. Whether you require special automation features, multiple millet varieties, or integration with other food processing lines, our engineering team can design the perfect solution.

Conclusion

The millet industry is witnessing a remarkable surge in demand, offering immense opportunities for entrepreneurs and businesses. Setting up a high-quality processing plant is essential to tap into this market effectively. Padsons Industries, a leading Millet Processing Plant Supplier in Maharashtra, provides state-of-the-art machinery, customised solutions, and reliable support to help businesses thrive. By choosing Padsons Industries, entrepreneurs not only ensure superior processing efficiency but also contribute to promoting health, sustainability, and rural development. We are the best Millet Processing Plant Supplier in Mumbai.

Padsons Industries guarantees that anyone wishing to invest in a millet processing factory will have access to top-notch equipment as well as the knowledge and assistance required for a prosperous enterprise. Your millet processing business can prosper in Maharashtra’s booming agricultural landscape with the correct technology and direction.