Wheat Cleaning Plant Manufacturer

Table of Contents

Introducion

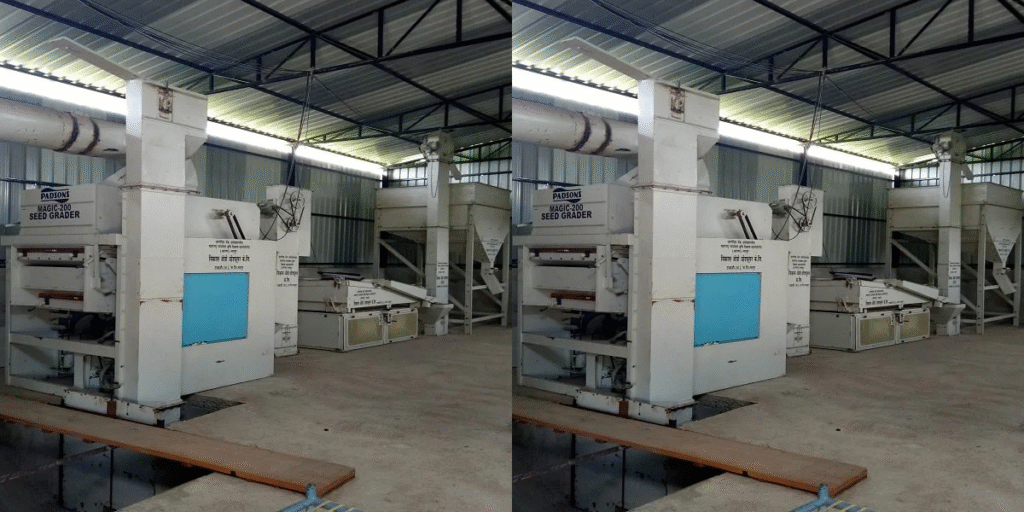

At Padsons Industries, we specialize in crafting user-friendly manual and semi-automatic farm machinery. With a focus on simplicity and effectiveness, our equipment is designed to make farming tasks more efficient and accessible for all. Our range includes a variety of tools that cater to the diverse needs of farmers. From easy-to-use plows to hassle-free seeders, we take pride in creating machinery that simplifies the farming process. With decades of experience in the industry, we understand the challenges faced by modern-day farmers. That’s why we’re dedicated to providing practical solutions that enhance productivity and yield. Trust Padsons Industries to be your reliable partner in agriculture.

More than merely a crop, wheat is essential to the world’s food security. It is the golden grain that has supported civilizations for thousands of years. Wheat is the basic component of our diets, appearing in everything from the basic loaf of bread to pasta, cakes, and innumerable more mainstays. However, this adaptable grain must go through a critical transformation—cleaning—before it can be made into delectable and healthful goods. We are the best Wheat Cleaning Plant Supplier.

Picture wheat that has just been plucked from the fields. A mixture of soil, dust, straw, stones, weed seeds, and even other grains, it is a natural treasure. The quality, safety, and effectiveness of further processing depend on this raw wheat receiving a comprehensive spa treatment. In order to prepare the grain for its voyage to our dinners, wheat cleaning plants serve as intricate purification centers.

Why Wheat Cleaning Plant

Cleaning wheat was a time-consuming, frequently manual procedure for centuries. Farmers would sort the good from the bad using wind and basic sieves. These techniques were time-consuming, ineffective, and unable to meet the purity standards required by contemporary markets, despite their limited effectiveness.Mechanical separators that used vibrating screens to eliminate contaminants were first used in the late 19th century. The demand for cleaner wheat was further highlighted by the introduction of continuous processing technologies and roller mills. Technologies like scourers, which use friction to remove surface filth, and aspiration, which uses air to remove lighter pollutants, became commonplace during the century. We are the best Wheat Cleaning Plant Exporter.

Why Choose Padsons Industries

- Years of Innovation and knowledge: Founded in as a member of the prestigious Padgilwar Group, Padsons Industries offers an unmatched breadth of knowledge. Continuous innovation, turning obstacles into opportunities, and continuously creating state-of-the-art seed and grain processing facilities have all been hallmarks of our path. Because of our long history, we are the ones that know the subtleties of wheat cleaning the best.

- Sturdy and Reliable Design: We are aware that agricultural equipment must endure harsh environments. Our wheat washing facilities are made with solid construction and premium materials like stainless steel to ensure their longevity. Season after season, this guarantees dependable operation, low breakdown rates, and long-lasting performance. We are delighted to say that our equipment is “Made in India,” meeting strict quality standards.

- Unmatched Accuracy and Efficiency: The wheat cleaning machines from Padsons Industries are designed to operate at their best. Our designs aim to minimize the loss of quality wheat while optimizing the separation of contaminants.

- Customized Solutions for Various Needs: Padsons Industries provides a variety of wheat cleaning machines with capacities ranging from and operation modes ranging from semi-automated to fully automatic, catering to both small-scale farmers and large-scale milling operations. We are aware of the various agricultural needs in India and are able to tailor solutions to work in harmony with your current configuration.

- Dedication to Excellence: At Padsons Industries, quality is more than simply a catchphrase; it’s part of our core values. Our manufacturing procedures meet the strictest international standards because we are an certified company. Every employee is dedicated to upholding these standards, and every raw material is subjected to stringent quality checks. Our many accolades, such as the “Rashtriya Udyog Ratna Award” from the Indian Organization for Business Research & Development and the “Best Agro Processing Machines Manufacturer & Exporter from in Maharashtra, attest to our unwavering commitment to excellence.

- Outstanding Post-Sale Assistance: For Padsons Industries, a sale signifies the start of an enduring collaboration. We take great satisfaction in our extensive network of farmers and our solid ties to the seed and milling sectors. In order to minimize downtime and maximize productivity, our committed customer support team is always available to help with installation, training, maintenance, and any technical questions you may have.

- Customer-Centric Approach: We support ongoing development motivated by input from our clients. To keep our products at the forefront of agricultural technology, we actively listen to our customers’ needs and make appropriate improvements. We have more than dealers and agents throughout India, as well as a solid network of devoted customers, thanks to this client-first strategy.

Applications of Wheat Cleaning Plants

1. Flour Mills

- Flour mills use wheat cleaning systems to prepare raw wheat for milling. Clean wheat ensures high-quality flour, which is essential for making bread, biscuits, cakes, noodles, and other products.

2. Seed Processing Units

- Seed producers need cleaned and graded wheat seeds for high germination and better storage. Our plants help in achieving seed purity and grading.

3. Agriculture Warehousing

- Storage of wheat without cleaning can lead to spoilage due to dust and moisture. Cleaning before warehousing increases shelf life and reduces losses.

4. Export Units

- Cleaned and polished wheat is in high demand in international markets. Padsons’ cleaning plants help exporters meet strict quality standards.

5. Food Processing Industries

- Companies involved in wheat-based snacks, cereals, and ready-to-eat products use cleaned wheat as their raw material to ensure hygiene and consistency.

6. Grain Export Companies

- Countries importing wheat have strict cleanliness norms. Wheat exporters use cleaning plants to meet international standards and avoid shipment rejections.

Specification Table for Wheat Cleaning Plant

| Specification | Model: PWC-5000 |

|---|---|

| Product | Wheat Cleaning Plant |

| Pre-cleaner Output | 98% impurity removal |

| Fine Cleaner | 3-layer sieves |

| Destoner Efficiency | 99% stone removal |

| Magnetic Separator | Rare earth magnets fitted |

| Aspirator System | Adjustable air suction |

| Power Required | 15 HP – 3 Phase |

| Dust Collector | High-efficiency cyclone separator |

| Material of Construction | MS + Powder Coated / SS Optional |

| Automation Level | Semi-Automatic / Fully Automatic |

| Floor Area Required | Approx. 25 ft x 15 ft |

| Warranty | 1 Year on manufacturing defects |

| Optional Add-ons | Grader, Color Sorter, Bucket Elevator |

Benefits of Wheat Cleaning Plant

- Excellent Flour Quality: This is the most obvious and important advantage. Clean wheat yields cleaner, purer flour that is devoid of foreign material particles. This enhances the flour’s overall baking performance, flavor, and appearance.

- Enhanced Food Safety: Wheat cleaning plants are essential to guaranteeing the safety and hygienic quality of the finished food product by eliminating dangerous impurities such as metals, stones, and even pesticide residues via washing in some sophisticated systems. Consumer confidence and adherence to global food safety regulations depend heavily on this.

- Improved Milling Efficiency and Longevity: Metal and stone impurities can seriously deteriorate costly milling equipment, resulting in frequent failures, high repair costs, and a shorter operational lifespan. Clean wheat reduces this damage, resulting in more efficient operations, fewer downtime, and longer equipment life.

- Decreased Product Loss and Waste: Good wheat is less likely to be inadvertently thrown out with contaminants when cleaning is done well. This maximizes the yield from your raw material, leading to better profitability.

- Increased Market Value: Wheat that is clean and of superior quality sells for more money. By continuously producing a better product, millers can improve their brand’s reputation and increase profits.

- Energy Efficiency: Optimized airflow systems and clever controls are used in modern wheat cleaning operations to minimize power usage while preserving good performance. This results in a smaller environmental impact and reduced operating expenses.

- Automation and Control: Modern cleaning facilities frequently have automation systems that keep an eye on operations, make real-time parameter adjustments, and notify operators of any problems. This provides constant performance, lowers the need for manual intervention, and enhances overall control.

Types of Wheat Cleaning Plants

1. Pre-Cleaner

- Purpose: Removes large impurities like stones, sticks, and straw.

- How it works: Uses air and sieve techniques.

- Padsons Model: Padsons Pre-Cleaner PC-Series — high efficiency and durable build.

2. Vibro Separator

- Purpose: Separates smaller impurities like sand and broken grains.

- Features: Vibro motors provide excellent grain flow.

- Padsons Advantage: Low noise operation, easy maintenance.

3. Destoner

- Purpose: Removes heavier particles like stones.

- Working: Gravity and air separation.

- Padsons Destoner DS-Series: Precision stone removal with high throughput.

4. Gravity Separator

- Purpose: Separates wheat based on density (removes light and immature grains).

- Why important: Improves milling quality.

- Our Solution: Padsons Gravity Separator GS-Series for maximum separation efficiency.

5. Aspirator

- Purpose: Removes husk, dust, and light particles.

- How it works: Uses airflow to lift lighter materials away from wheat.

- Padsons Benefit: Energy-efficient aspirator with minimal grain loss.

6. Magnetic Separator

- Purpose: Eliminates metallic impurities.

- Why necessary: Protects downstream machinery.

- Padsons Magnetic Separator: High-grade magnets ensure safety and purity.

7. Rotary Drum Cleaner

- Purpose: Initial heavy cleaning stage for large contaminants.

- Features: Cylindrical drum with perforated screens.

- Padsons RDC-Series: Rugged design for continuous operation.

Conclusion

It is impossible to overestimate the importance of a wheat cleaning facility in the broad and complex field of food processing. The safety, quality, and marketability of the finished flour product are determined by this crucial initial phase. By carefully eliminating impurities, these facilities not only preserve the health of consumers but also protect costly grinding equipment and maximize companies’ profits. Wea re the best Best Wheat Cleaning Plant Manufacturer.

For millers seeking for consistent quality, operational efficiency, and a competitive advantage in the market, investing in a state-of-the-art wheat cleaning plant from a respected Wheat Cleaning Plant Manufacturer like Padsons Industries is not only an option, but an essential necessity. We cordially encourage you to discover the Padsons distinction, where quality is consistently the pillar and performance meets perfection.