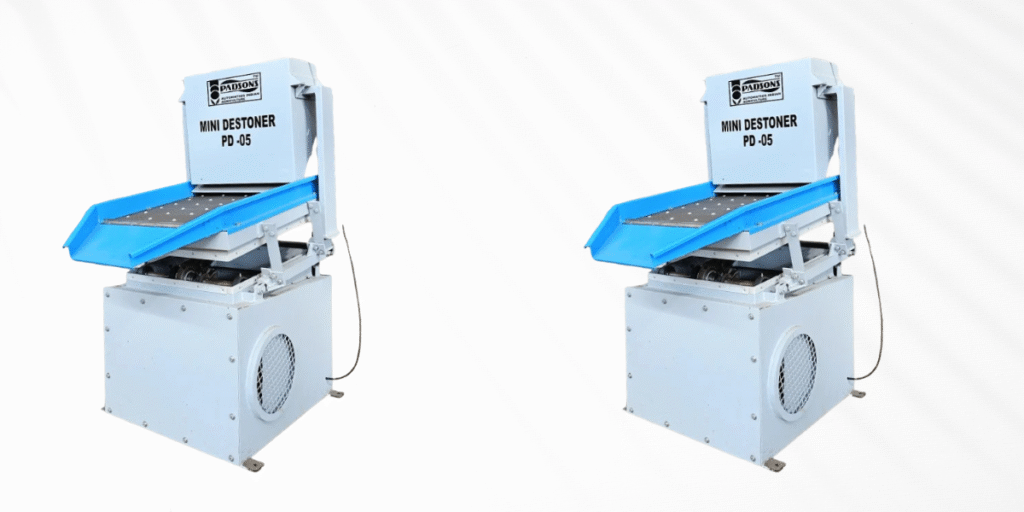

Vibro Destoner Supplier in Maharashtra

Introduction

At Padsons Industries, we specialize in crafting user-friendly manual and semi-automatic farm machinery. With a focus on simplicity and effectiveness, our equipment is designed to make farming tasks more efficient and accessible for all. Our range includes a variety of tools that cater to the diverse needs of farmers. From easy-to-use plows to hassle-free seeders, we take pride in creating machinery that simplifies the farming process. With decades of experience in the industry, we understand the challenges faced by modern-day farmers. That’s why we’re dedicated to providing practical solutions that enhance productivity and yield. Trust Padsons Industries to be your reliable partner in agriculture.

Efficiency and quality are critical in today’s agriculture and food processing industries. The vibro destoner is one of the essential pieces of machinery that guarantees exceptional product quality. These devices are essential for sorting grains, pulses, spices, seeds, and other heavy contaminants like stones and pebbles. Padsons Industries is your go-to source for a dependable vibro destoner supplier in Maharashtra, offering top-notch machinery customized to your production requirements. We are the best Vibro Destoner Manufacturer.

What is a Vibro Destoner

One essential piece of equipment in the food processing sector is a vibro destoner. Its main purpose is to rid grains, legumes, and seeds of heavy contaminants like stones and pebbles. Vibro destoners not only improve product quality by removing these undesirable impurities, but they also shield downstream machinery such as mills, polishing machines, and grinders from harm.The machine operates on the straightforward tenet of air separation and vibration. As grains move across a vibrating deck, heavier contaminants, such as stones, are separated from the lighter grains by density differences. Clean, superior produce that is prepared for additional processing or packaging is the end result. We are the best Vibro Destoner Exporter.

Why Choose Padsons Industries

- Unmatched Engineering and Robust Build Quality: We don’t believe in cutting corners. Our Vibro Destoners are built with high-grade materials and components to withstand the rigors of continuous industrial use. A robust machine means fewer breakdowns, lower maintenance costs, and a much longer lifespan, giving you a superior return on your investment.

- High Capacity with Uncompromised Efficiency: Time is money. Our machines are designed for high-throughput operations without sacrificing separation efficiency. You can process large volumes of material quickly, ensuring that your production targets are met consistently. Our destoners effectively remove not just stones but also heavier immature grains and glass particles.

- Customizable Solutions for Your Unique Needs: We understand that no two processing plants are identical. That’s why we offer customizable solutions. Whether you need a specific deck mesh, a different motor capacity, or a tailored airflow system, we can configure our Vibro Destoner to match your specific raw material and output requirements perfectly.

- Energy-Efficient Operation: In today’s world, energy conservation is crucial for both cost-saving and environmental responsibility. Padsson’s Vibro Destoners are designed to deliver maximum output with minimal power consumption, helping you reduce your operational expenses and carbon footprint.

- Ease of Use and Low Maintenance: Our machines are user-friendly. The cleaning decks are easily accessible, and the settings are simple to adjust. This translates to less time spent on operator training and routine maintenance, freeing up your team to focus on other critical tasks.

- High Efficiency for Maximum Profitability: The core reason you buy a destoner is for results. Padsons’ Vibro Destoners are designed to remove up to 99% of stones, glass, and other heavy contaminants. More importantly, we achieve this with a very low percentage of good grain loss. This means you get more saleable product out of every batch, directly boosting your bottom line.

- Energy-Efficient Operation: In today’s world, saving energy is saving money. Our machines are designed to deliver maximum output while consuming minimal power. This reduces your operational costs day after day, making your business more sustainable and profitable.

- Ease of Use and Low Maintenance: We believe technology should simplify your work, not complicate it. Padsson’s Vibro Destoners are user-friendly, with intuitive controls that your operators can learn quickly. Their design is also streamlined for easy cleaning and maintenance, minimizing downtime and keeping your production line running smoothly.

- Customized Solutions: We know that every processing plant is unique. Are you cleaning basmati rice, or are you processing lentils? The size, density, and flow rate matter. We don’t believe in a one-size-fits-all approach. Our technical team works with you to understand your specific raw material and capacity requirements, recommending the perfect Vibro Destoner model for your line.

Applications of Vibro Destoners

1. Rice Mills

- In rice processing, stones and pebbles can damage the huller or polisher. Vibro destoners ensure only clean paddy grains enter the milling process, enhancing output quality and reducing machine maintenance costs.

2. Wheat and Flour Mills

- Wheat processing requires clean grains for producing high-quality flour. Vibro destoners effectively remove stones, metal fragments, and other impurities before grinding, ensuring fine flour production.

3. Pulses and Legumes Processing

- Pulses such as chickpeas, lentils, and beans often come mixed with small stones. Vibro destoners ensure that the pulses are pure, safe, and ready for packing or further processing.

4. Spices and Seeds Processing

- Seeds like sesame, mustard, sunflower, and spices such as pepper and cumin need thorough cleaning. Stones or hard particles in these products can affect quality and taste. Vibro destoners provide precision cleaning to meet industrial standards.

5. Feed and Animal Husbandry

- Animal feed requires clean grains to prevent machinery damage and ensure livestock health. Vibro destoners remove stones and other impurities, making feed production safer and more efficient.

6. Export-Oriented Units

- For businesses targeting international markets, quality standards are strict. Stones, metal fragments, and impurities can lead to rejection. Vibro destoners ensure grains meet stringent export criteria.

7. Spices and Herbal Products

- Many spices like turmeric, coriander, and cumin often contain small stones or heavy dirt particles. Using a vibro destoner improves the quality and safety of spices, which is essential for both domestic and export markets.

Specifications Table of Vibro Destoner

| Parameter | Specification |

|---|---|

| Material | Vibro Destoner |

| Screen Material | Stainless Steel / Mild Steel |

| Motor Power | 1–5 HP |

| Vibration Frequency | 1200–1500 RPM |

| Frame Material | Mild Steel / Stainless Steel |

| Dimensions (L×W×H) | 2000×1000×1200 mm |

| Weight | 250–400 kg |

| Power Supply | 220/440 V, 50 Hz |

Benefits of Vibro Destoner

- Superior Separation Efficiency: The core of our design focuses on achieving the highest possible separation efficiency. Our precisely calculated vibration frequency and amplitude, combined with an efficient air aspiration system, ensure that even the trickiest of impurities—like stones of similar size to the grain—are effectively removed.

- Energy-Efficient Operation: We understand that running costs matter. Padsons’ Vibro Destoners are designed with optimized motors and drive systems that consume less power without compromising on performance, helping you save on your electricity bills.

- Gentle on Grains: The cleaning process should not damage the grains. Our destoners are designed to handle the product gently, preventing breakage and preserving the integrity and appearance of your output, which is crucial for getting the best market price.

- Easy to Operate and Maintain: We believe in simplicity. Our machines are user-friendly, with easy-to-adjust settings for different products. The design allows for quick disassembly for cleaning and maintenance, reducing downtime and ensuring hygiene.

- Customization for Your Needs: No two processing plants are exactly alike. Whether you need a specific capacity, a different deck size, or a special configuration to handle a unique product, we have the expertise to customize our Vibro Destoner to fit your exact requirements perfectly.

- Protection for Downstream Machinery: Stones and metal pieces are notorious for damaging expensive processing equipment like polishers, graders, and rollers. A destoner acts as a guardian, protecting your other machinery and saving you from high repair costs and downtime.

- Increased Efficiency & Yield: By cleanly separating unwanted materials, you are not paying to process, package, and transport waste. This improves your overall yield and operational efficiency.

- Meets Quality Standards: For businesses looking to export or supply to large retailers, meeting strict food safety and quality standards (like FSSAI) is mandatory. A destoner is a critical step in achieving that compliance.

- Ensures Product Safety & Quality: This is the most critical reason. A single small stone in a packet of rice or dal can lead to a broken tooth and a major consumer complaint. It protects your brand’s reputation and ensures you meet food safety standards.

- Increases Your Profitability: By removing inedible impurities, you are effectively selling more of your actual product by weight. Clean, high-quality produce also commands a better price in the market.

Types of Vibro Destoners

1. Single Deck Vibro Destoner

- Single deck vibro destoners are designed for small to medium capacity operations. They consist of a single vibrating tray that separates stones from grains. These are ideal for rice, pulses, and seeds.

2. Double Deck Vibro Destoner

- Double deck vibro destoners are perfect for medium to large capacity operations. They consist of two layers of vibrating trays. The top tray removes stones, while the bottom tray can remove smaller impurities.

3. Fully Automatic Vibro Destoner

- For large-scale industrial operations, fully automatic vibro destoners provide the best performance. These machines are equipped with advanced control systems that automate the separation process.

4. Portable Vibro Destoner

- Portable vibro destoners are designed for flexibility and easy relocation. These are suitable for small farmers or processors who need a machine that can be moved between locations.

5. Two-Deck Vibro Destoner

- A two-deck system provides double-layer separation for maximum purity. The first deck removes heavier stones, and the second deck ensures fine separation of smaller impurities.

Conclusion

Ensuring product purity and operational efficiency is crucial in the cutthroat agricultural and food processing industries of today. In order to accomplish these objectives, vibro destoners are essential. Padsons Industries, a reputable Vibro Destoner Supplier in Maharashtra, meets each customer’s needs by combining high-quality equipment, knowledgeable advice, and first-rate service. We are the Best Vibro Destoner Supplier.

Working together with Padsons Industries ensures clean goods, increased production, and long-term dependability whether you are processing grains, pulses, seeds, or spices. For your Vibro Destoner needs, pick Padsons Industries and see the difference in performance and quality.