Spiral Plant Supplier in Maharashtra

Introduction

At Padsons Industries, we specialize in crafting user-friendly manual and semi-automatic farm machinery. With a focus on simplicity and effectiveness, our equipment is designed to make farming tasks more efficient and accessible for all. Our range includes a variety of tools that cater to the diverse needs of farmers. From easy-to-use plows to hassle-free seeders, we take pride in creating machinery that simplifies the farming process. With decades of experience in the industry, we understand the challenges faced by modern-day farmers. That’s why we’re dedicated to providing practical solutions that enhance productivity and yield. Trust Padsons Industries to be your reliable partner in agriculture.

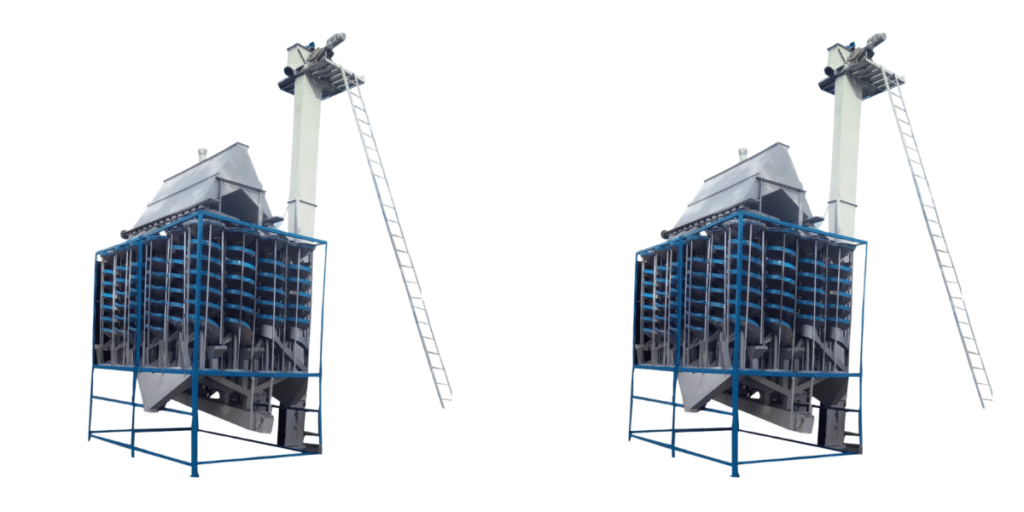

Modern technology and automated systems are essential for enhancing efficiency, decreasing labor costs, and boosting production in today’s expanding industrial and agricultural sectors. The Spiral Plant, a sturdy and dependable solution for managing bulk materials in a variety of industries, including agricultural, food processing, plastic recycling, and more, is one such crucial invention. Look no farther than Padsons Industries, a brand known for excellence, efficiency, and client satisfaction, if you’re looking for a reliable spiral plant supplier in Maharashtra. We are the best Spiral Plant Manufacturer.

What is a Spiral Plant

A spiral plant is an industrial facility that uses spiral conveyors or spiral separators to process, move, or separate commodities. Industries that deal with powders, granules, seeds, grains, pellets, or minerals frequently use these plants. While occupying the least amount of floor space, the spiral form guarantees constant and effective material circulation. Because of this, spiral plants are perfect for both large and small industrial facilities. We are the best Best Spiral Plant Supplier.

Why Choose Padsons Industries

- Unwavering Commitment to Quality. Quality is the cornerstone of everything we do at Padsson Industries. We source our raw materials from trusted vendors and subject them to rigorous checks. Our skilled welders and technicians are trained to the highest standards, and every finished unit undergoes a series of non-destructive and hydrostatic tests to guarantee it can withstand the demands of your operation.

- End-to-End In-House Manufacturing. We are proud to be manufacturers, not just traders. Our state-of-the-art manufacturing facility is equipped with advanced machinery, allowing us to maintain complete control over every stage of production. From cutting and rolling the plates to welding and pressure testing, every step is meticulously monitored by our quality assurance team. This ensures that every spiral plant that leaves our unit is built to last and perform flawlessly.

- Bespoke Engineering Solutions. We understand that a one-size-fits-all approach doesn’t work in industry. Maybe you need a specific material of construction to handle a corrosive fluid. Perhaps your space constraints are extremely tight. At Padsons, we thrive on these challenges. We work closely with you to design a custom spiral heat exchanger that fits your process like a glove, ensuring optimal performance and efficiency.

- Deep Industry Expertise and Customization We understand that no two industrial processes are the same. A spiral plant that works for a dairy in Kolhapur may not be suitable for a chemical plant in Tarapur. That’s why we offer fully customized solutions. Our team of experienced engineers works closely with you to understand your specific requirements fluid properties, temperature ranges, pressure levels, and space constraints—to design a spiral plant that fits your process perfectly.

- Commitment to Timely Delivery In industry, time is money. We respect your project timelines and production schedules. Our streamlined manufacturing processes and efficient supply chain management allow us to deliver your custom-built Spiral Plant within the promised timeframe, helping you keep your projects on track.

- Cost-Effectiveness in the Long Run While our initial focus is on quality, this approach ultimately saves you money. A reliable, efficient Spiral Plant from Padsons reduces your energy consumption, minimizes maintenance costs, and prevents expensive production stoppages. You don’t just buy a product; you invest in operational stability and lower total cost of ownership.

- Custom-Engineered Solutions: Your business is unique, and your spiral plant should be too. We don’t believe in a one-size-fits-all approach. Our team of expert engineers works closely with you to understand your material characteristics abrasiveness, flowability, moisture content apacity requirements, and spatial constraints. We then design and fabricate a spiral plant that fits your process like a glove.

- Focus on Efficiency and Performance: An inefficient conveyor can be a silent profit-killer. Our spiral plants are engineered for smooth, consistent, and energy-efficient operation. The precise design ensures maximum throughput with minimal power consumption, directly impacting your bottom line.

- Comprehensive Service and Support: Our relationship doesn’t end with a sale. We provide complete support, from installation and commissioning to after-sales service and maintenance. Our readily available spare parts and responsive service team ensure that your operations run smoothly with minimal downtime.

Applications of Spiral Plants

1. Food Processing Industry

- In the food industry, spiral systems are used for cooling, freezing, baking, and conveying food products. Spiral freezers and coolers help maintain product quality while saving time and energy.

2. Mining and Mineral Processing

- Spiral plants are widely used in mining industries to separate valuable ores like iron, chromite, coal, and mineral sands. The spiral concentrator helps improve the recovery rate and purity of minerals.

3. Coal Washing and Beneficiation

- In the coal industry, Spiral Plants are employed for the washing and upgrading of coal. They help in removing impurities and improving the calorific value of coal, making it more efficient for power generation and industrial fuel.

4. Sand and Silica Processing

- For producing high-purity silica sand used in glass manufacturing, construction, and foundries, Spiral Plants ensure precise separation of impurities like clay, silt, and unwanted minerals.

5. Iron Ore Beneficiation

- Spiral concentrators help in the concentration of low-grade iron ores, enhancing the Fe content and reducing impurities like silica and alumina.

6. Environmental Waste Management

- Spiral Plants are also used in recycling industries for separating metal particles, glass, and plastics based on density. This helps in sustainable waste management and resource recovery.

7. Beach Sand Mining

- Used for the recovery of heavy minerals such as garnet, zircon, and rutile from beach sands, Spiral Plants are crucial in coastal mineral processing industries.

8. Chemical and Metallurgical Industries

- Spiral Plants are integrated into various metallurgical and chemical processes to separate raw materials efficiently, ensuring high product quality and reduced processing time.

Table Specifications of Spiral Plant

| Parameter | Specification |

|---|---|

| Material | Spiral Plant |

| Type | Gravity Spiral Separator |

| Spiral Diameter | 600 mm to 1500 mm |

| Number of Starts | 1 to 4 starts per module |

| Feed Size | 0.1 mm to 5 mm |

| Capacity | 1 to 20 TPH (depending on material) |

| Material of Construction | Mild Steel / Stainless Steel |

| Power Requirement | 2 – 10 HP |

| Separation Efficiency | Up to 98% |

| Application | Mineral, Sand, Coal, and Industrial Material Separation |

| Optional Features | Adjustable flow control, corrosion-resistant coating, automated feed system |

Benefits of Spiral Plant

- Handles Dirty Fluids with Ease: Unlike traditional shell and tube heat exchangers that get clogged easily, the spiral design has a single, wide channel. This allows liquids with sludge, slurries, or particles to pass through without blocking the system. This means less downtime and more productivity.

- Superior Quality and Durability: Quality is non-negotiable. We use only the highest-grade materials, including stainless steel and other special alloys, to combat corrosion and withstand high pressures and temperatures. Our robust manufacturing and stringent quality checks ensure that every Spiral Heat Exchanger we deliver is built to last, giving you peace of mind and a great return on your investment.

- Significant Cost Savings: Our spiral heat exchangers are designed for efficiency. By maximizing heat transfer, they significantly reduce your energy consumption, directly cutting down your operational costs. Furthermore, their low-maintenance design means you save heavily on cleaning, downtime, and repair expenses over the years.

- Compact and Space-Saving Design: We understand the space challenges in modern industrial setups. Our compact and intelligently designed units help you save valuable floor space, allowing for a more efficient and organized plant layout.

- Reliable After-Sales Support: Our relationship doesn’t end with a sale. Padsson Industries is known for its strong and responsive after-sales service. From installation guidance to providing timely spares and technical support, our team is always ready to ensure your operations run smoothly without any interruptions.

- Massive Space Savings: This is the biggest advantage. Traditional conveyor systems that move products between floors or across long distances require a large footprint. A spiral system uses vertical space, doing the same job in a fraction of the floor area. In a state like Maharashtra, where real estate is at a premium, this is a game-changer.

- Enhanced Efficiency and Continuous Flow: Spiral conveyors allow for a non-stop, smooth movement of materials. There are no transfers or stops between different conveyor belts, which minimizes bottlenecks and speeds up your entire production or dispatch line.

- Gentle Product Handling: Whether you’re conveying delicate biscuit packets, glass bottles, or electronic components, modern spiral systems are designed with gentle curves and stable platforms. This significantly reduces the risk of damage, breakage, and product loss, saving you money and maintaining quality.

- Energy Efficiency: A single motor drives the entire spiral system, making it far more energy-efficient than a complex network of multiple straight conveyors. This leads to lower operational costs and a smaller carbon footprint.

- Versatility and Scalability: Spiral plants are not one-size-fits-all. They can be customized to handle a wide range of products, weights, and speeds. As your business in Maharashtra grows, a good spiral system can be adapted and scaled to meet your new demands.

Types of Spiral Plants

1. Spiral Conveyor Plants

- These are used for vertical material transportation in limited spaces. Ideal for packaging, food, beverage, and assembly industries, spiral conveyors help move materials between floors efficiently.

2. Spiral Separators

- Spiral separators are mainly used for gravity separation in mining and mineral processing. They separate particles based on density and shape, ideal for coal, iron ore, and sand industries.

3. Spiral Classifier Plants

- Commonly used in mineral beneficiation and sand washing, spiral classifiers separate and clean materials by particle size and density.

4. Spiral Cooling Systems

- Used in food processing industries, these spiral systems cool baked goods, dairy products, and packaged food items while maintaining hygiene and freshness.

5. Spiral Freezer Plants

- These are used in cold storage and frozen food industries to quickly freeze food items while preserving quality and taste.

Conclusion

Purchasing top-notch equipment is essential for productivity and long-term expansion in the cutthroat business world of today. Padsons Industries is your dependable partner if you’re looking for a trustworthy supplier of spiral plants in Maharashtra. Padsons guarantees that every spiral plant produces consistent results through great engineering, high performance, and unparalleled customer service.

Padsons Industries is your best option if you’re searching for a reliable supplier of spiral plants in Maharashtra. Padsons keeps raising the bar for industrial manufacturing with its dedication to quality, personalization, and client satisfaction.