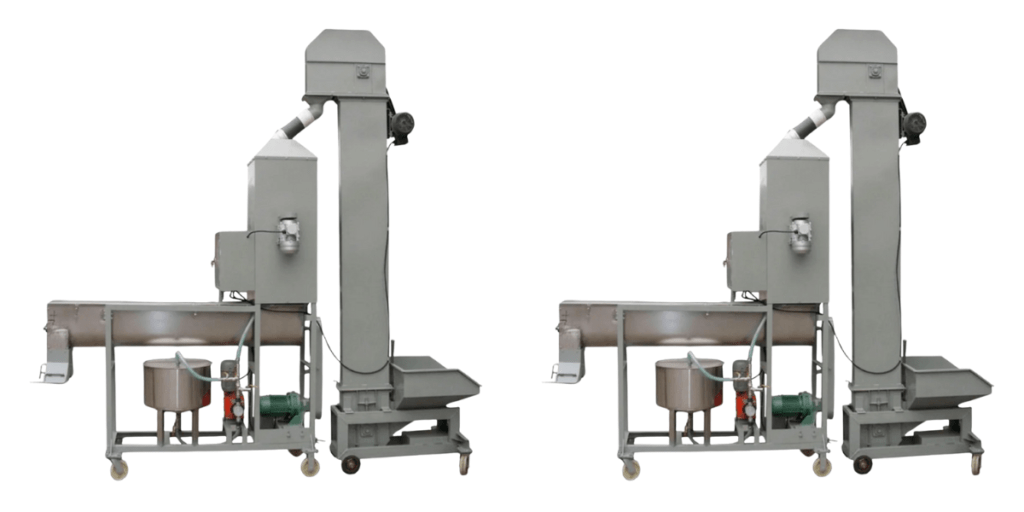

Seed Treater Manufacturer

Introduction

At Padsons Industries, we specialize in crafting user-friendly manual and semi-automatic farm machinery. With a focus on simplicity and effectiveness, our equipment is designed to make farming tasks more efficient and accessible for all. Our range includes a variety of tools that cater to the diverse needs of farmers. From easy-to-use plows to hassle-free seeders, we take pride in creating machinery that simplifies the farming process. With decades of experience in the industry, we understand the challenges faced by modern-day farmers. That’s why we’re dedicated to providing practical solutions that enhance productivity and yield. Trust Padsons Industries to be your reliable partner in agriculture.

In agriculture, each minuscule seed embodies the potential for a generous harvest. However, fulfilling that promise is not always easy. Once seeds are planted, they encounter various dangers, including soil-borne diseases, voracious insects, and erratic climatic factors. It is here that seed treaters, the uncelebrated champions of agriculture, make their contribution. We at Padsons Industries recognize the vital importance of Seed Treaters in securing successful crops, as we manufacture these machines ourselves. This article will explore the nature of seed treaters, their essential role in contemporary agriculture, and the reasons Padsons Industries is recognized as a leader in offering innovative solutions. We are the best Seed Treater Supplier.

What Exactly is a Seed Treater

Envision a minuscule seed, no larger than a speck of dust, containing the promise of an abundant yield. It is vulnerable before it even touches the ground. Seed-borne diseases may lie dormant within the seed, soil-borne fungi can strike as soon as it germinates, and early-season insects can prey on its delicate young seedlings. Without protection, many seeds may fail to reach their full potential, resulting in lower yields and resource waste. We are the best Seed Treater Exporter.

Why Choose Padsons Industries

- Proven Reliability and Decades of Expertise: Founded in 1999, Padsons Industries offers more than twenty years of practical experience. This concerns more than just the manufacturing of machines; it concerns grasping the difficulties encountered by farmers and seed processors, along with devising effective solutions. The reliability and performance of our equipment are evidenced by our long-standing presence in the market.

- Cutting-Edge Technology Within Reach: At Padsons Industries, we dedicate ourselves to ongoing innovation. To guarantee the best possible performance, our seed treaters utilize advanced features and contemporary engineering principles. For example, our Mist-O-Matic Seed Treater is intended for.

- Tailored Solutions for Diverse Needs: We understand that every seed processing operation is unique. Whether you’re a small-scale farmer looking for a compact solution or a large seed producer requiring high-capacity continuous treaters, Padsons Industries can offer customized solutions. Our range of seed treaters with varying capacities (e.g., 2 TPH models) ensures we can meet diverse requirements. We also manufacture a wide range of other seed processing machinery, allowing us to provide comprehensive plant solutions.

- Focus on Quality and Performance: Quality is not just a buzzword at Padsons Industries; it’s ingrained in our manufacturing process. We adhere to stringent quality control measures to ensure that every seed treater leaving our facility meets the highest standards of performance and reliability. Our machines are designed to enhance seed quality, improve germination rates, and ultimately contribute to higher yields for our clients.

- Cost-Effectiveness: Padsons Industries aims to provide solutions that are economical while delivering high-quality technology and strong construction. We believe that advanced agricultural machinery should be affordable, enabling farmers to achieve better returns on their investments without incurring excessive costs. We aim to provide machines that deliver superior value and quick returns on investment by enhancing crop yields.

- All-encompassing Support and Service: Our client relationships go beyond mere transactions. Padsons Industries is dedicated to offering outstanding after-sales support, which encompasses help with installation, training, and easy access to spare parts. We are committed to establishing enduring collaborations with our clients, which guarantees their ongoing success.

- Contribution to Sustainable Agriculture: By enabling precise and efficient seed treatment, Padsons Industries’ equipment plays a crucial role in promoting sustainable agricultural practices. Targeted application of treatments reduces the overall chemical footprint, leading to healthier ecosystems and more environmentally responsible farming.

Applications of Seed Treater

- High Capacity: Our industrial seed treaters are engineered for high throughput, with the ability to process tons of seed each hour. This is vital for significant seed processing units, agricultural cooperatives, and large-scale farming businesses.

- Exactness and Consistency: We recognize the importance of each individual seed. Our equipment employs cutting-edge dosing and mixing methods, such as spinning discs for consistent slurry application, to guarantee that each seed gets the exact amount of treatment it requires. This results in uniform protection and ideal germination throughout all of your land.

- Durable and Reliable: Built with premium materials and meticulous engineering, Padsons seed treaters are renowned for their long-lasting nature and durability. They are constructed to withstand the rigors of continuous, heavy-duty use in demanding agricultural environments, guaranteeing a lengthy operational life.

- Versatile for Various Seeds: Whether you’re treating cotton, corn, cereals, or other crops, Padsons Industries offers seed treaters that can handle a wide variety of seed types and sizes. Our machines are adaptable to different treatment formulations, from fungicides and insecticides to biologicals and nutrients.

- Ease of Operation and Maintenance: While our machines are technologically advanced, we prioritize user-friendliness. Our designs focus on simple operation and accessible maintenance, minimizing downtime and maximizing productivity.

- Customizable Solutions: We understand that every large-scale operation has unique requirements. Padsons Industries works with clients to provide customizable seed treater solutions that integrate seamlessly into existing processing lines, offering tailored capacities and functionalities.

- Design and Engineering: Modern seed treaters are designed for precision and efficiency. This involves careful consideration of the type of seeds to be treated, the kind of treatment agents to be applied (dusts, slurries, liquids, or even a combination), and the desired throughput capacity. Manufacturers focus on creating systems that ensure even coating and minimal waste.

- Material Selection: Durability is paramount. Seed treaters are exposed to various chemicals and abrasive seed materials, so robust construction using high-quality stainless steel and other resistant materials is crucial for longevity and reliable operation.

- Integration of Automation and Control: For large-scale applications, automation is key. This includes electronic scales for precise dosing of seeds, automated slurry and powder dosing systems, and advanced control panels that allow operators to monitor and adjust treatment parameters. Continuous flow treaters, which handle a steady stream of seeds, are especially important in industrial settings.

Specifications Table of Seed Treater

| Specification | Details |

|---|---|

| Model Name | Padsons Seed |

| Capacity | 500 Kg per Hour |

| Type | Batch Type / Continuous Type |

| Power Requirement | 3 HP / 5 HP Electric Motor |

| Chemical Dosage Accuracy | ± 2% |

| Seed Type Compatibility | Wheat, Rice, Maize, Soybean, Pulses, and more |

| Machine Material | Mild Steel / Stainless Steel |

| Control Panel | Digital / PLC-based (Optional) |

| Dimensions (L x W x H) | 1500 x 800 x 1400 mm |

| Warranty | 1 Year |

Benefits of Seed Treatment

- Enhanced Germination and Early Vigor: Treated seeds are better protected from early-season threats, leading to higher germination rates and more vigorous, uniform seedling emergence. This means more plants per acre and a stronger start to the crop cycle.

- Protection Against Pests and Diseases: Seed treatments provide critical protection against soil-borne and seed-borne pathogens, as well as early-season insect pests. This reduces crop losses and the need for costly in-field pesticide applications later.

- Reduced Chemical Load in the Environment: By applying targeted treatments directly to the seed, the overall amount of pesticides or fungicides used can be significantly reduced compared to broadcast spraying. This is more environmentally friendly and helps preserve beneficial insects and soil microorganisms.

- Improved Crop Stand and Yield: A healthy, uniform crop stand is the foundation of high yields. Seed treatment ensures that each plant has the best chance to reach its full genetic potential, leading to increased productivity and profitability for farmers.

- Better Management of Stress Conditions: Some seed treatments can enhance the seed’s tolerance to environmental stresses like drought, cold, or salinity, making crops more resilient in challenging climates.

- Cost-Effectiveness: While there’s an initial cost for seed treatment, the benefits often outweigh it significantly. Reduced crop losses, fewer in-field applications, and higher yields contribute to a better return on investment for farmers.

- Efficient Nutrient Uptake: Certain treatments, especially those with microbial inoculants or micronutrients, can improve the plant’s ability to absorb essential nutrients from the soil, leading to healthier growth.

- Convenience and Efficiency: Treating seeds before planting simplifies the planting process, as farmers don’t need to worry about applying treatments in the field during critical early growth stages.

Types of Seed Treaters

1. Batch Type Seed Treater

- The Batch Type Seed Treater is designed for treating a fixed quantity of seeds in each cycle. It ensures accurate chemical dosing and uniform seed coating.

Features:

- Easy to operate and clean

- Suitable for small to medium-scale operations

- Adjustable dosing system

- Gentle seed handling

2. Continuous Type Seed Treater

- The Continuous Type Seed Treater allows for uninterrupted seed treatment operations, where seeds are fed continuously, treated, and discharged.

Features:

- High treatment capacity

- Uniform and consistent coating

- Ideal for large-scale seed processing plants

- Advanced metering system for precise chemical application

3. Drum Type Seed Treater

- This type of Seed Treater uses a rotating drum to evenly mix seeds and treatment chemicals. It ensures excellent coating quality and is suitable for various seed types.

Features:

- Compact and sturdy design

- Uniform chemical distribution

- Easy loading and unloading

- Low maintenance

4. Rotary Seed Treater

- The Rotary Seed Treater is known for its high-speed operation and consistent chemical application. It’s efficient, versatile, and suitable for different seed sizes.

Features:

- High capacity output

- User-friendly controls

- Accurate dosing system

- Smooth seed movement without damage

Conclusion

A seed’s journey from soil to harvest is filled with difficulties. Yet, when adequately prepared and protected, the potential is boundless. Seed treaters play a crucial but often overlooked role in this process, making certain that each seed begins its life under the most favorable conditions. They are essential instruments for contemporary farming, playing a major role in food security and economic well-being. We are the best Best Seed Treater Manufacturer.

Farmers and seed processors in search of a reliable partner for this essential agricultural component need look no further than Padsons Industries, which boasts an exceptional track record, a dedication to innovation, and a selection of premium seed treaters aimed at maximizing the potential of each seed. When you select Padsons, you’re doing more than purchasing a machine; you are putting your money into a future of agriculture that is more sustainable, productive, and profitable.