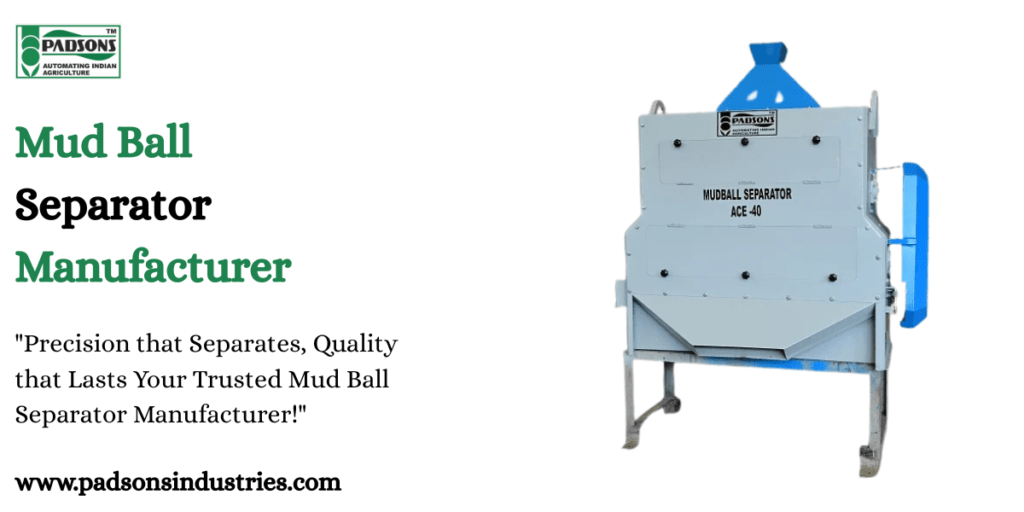

Mud Ball Separator Manufacturer

Table of Contents

Introduction

At Padsons Industries, we specialize in crafting user-friendly manual and semi-automatic farm machinery. With a focus on simplicity and effectiveness, our equipment is designed to make farming tasks more efficient and accessible for all. Our range includes a variety of tools that cater to the diverse needs of farmers. From easy-to-use plows to hassle-free seeders, we take pride in creating machinery that simplifies the farming process. With decades of experience in the industry, we understand the challenges faced by modern-day farmers. That’s why we’re dedicated to providing practical solutions that enhance productivity and yield. Trust Padsons Industries to be your reliable partner in agriculture.

Picture a farmer laboring away in the fields, caring for their crops from planting to harvest. Picture those harvested crops, meant for the market or additional processing, arriving tainted with clinging mud balls. This goes beyond mere inconvenience—it’s a serious issue that can result in diminished quality, inefficiencies in processing, and considerable financial losses. We are the best Mud Ball Separator Supplier.

Here is where the mud ball separator comes into play: an essential item of farming equipment that frequently escapes attention but is key to guaranteeing clean, high-quality produce.Padsons Industries, a prominent manufacturer of Mud Ball Separators, recognizes the complex engineering and significant worth of these machines. We are here to thoroughly explore the essence of mud ball separators, their essential role in contemporary agriculture and food processing, and the reasons behind Padsons Industries’ reputation as a reliable and pioneering leader in this niche.

Why Mud Ball Separator

Prior to our appreciation of the solution, let’s grasp the problem. Root crops such as potatoes, onions, carrots, and sugar beet, along with certain grains, are directly harvested from the soil. No matter how careful the harvesting methods are, some soil will be picked up along with the crop, as this is almost unavoidable. This soil forms clumps of different sizes, known as “mud balls,” when it is moist. We are the best Mud Ball Separator Exporter.

Why Choose Padsons Industries

- Commitment to Engineering Excellence and Robust Design: Our conviction is that machines should endure. Designed for lasting performance, our mud ball separators are built with premium materials and sturdy construction methods to endure the challenges of tough industrial settings. We focus on efficiency in our designs, guaranteeing that mud balls are removed to the greatest extent possible while energy use is kept to a minimum.

- Tailoring to Your Individual Requirements: We recognize that each operation is one of a kind. No matter if you are working with clay that is extremely adhesive, large quantities, or particular properties of material, our skilled engineers can create and tailor mud ball separators to suit your needs precisely. To provide a customized solution that optimizes your efficiency, we offer a range of capacities, configurations, and features.

- Demonstrated Performance and Dependability: Our machines are not only designed; they have been validated in real-world conditions. Our dependable mud ball separators have helped clients from various sectors boost productivity, achieve cleaner products, and lessen operational challenges. Our history demonstrates that we have provided solutions that consistently perform at a high level.

- Cutting-edge technology and innovation: Padsons Industries makes ongoing investments in R&D to integrate the most recent technological advancements into our equipment. This guarantees that our mud ball separators excel in efficiency, user-friendliness, and minimal upkeep.

- All-encompassing Assistance and Service: Our dedication to our clients goes well beyond the point of sale. To guarantee that your mud ball separator runs seamlessly for many years, we offer all-encompassing technical assistance, availability of spare parts, and after-sales service. You can count on our team to help you with installation, training, and troubleshooting.

- Situated in Ghaziabad, Uttar Pradesh: Our strategic position in Ghaziabad, a key industrial center, provides us with efficient access to raw materials, skilled workforce, and logistics networks, facilitating effective service to our clients across India and beyond.

Applications of Mud Ball Separator

- Potatoes, carrots, onions, and beets: This is among the most frequent uses. These root vegetables are harvested with soil, stones, and mud balls attached to them. Before washing, grading, and packaging, separators are essential for ensuring clean produce and preventing damage to downstream processing equipment.

- Sugar Beet Processing: Mud balls found in sugar beets pose a serious problem, as they can cause considerable sugar loss and damage to factory equipment. Large-scale separators are crucial during the intake stage.

- Grains and Pulses: Although it is not typical for “mud balls,” certain grain cleaning methods may apply comparable principles to eliminate clumps of waste.

- Sand & Gravel Quarries: The aggregates obtained often contain clay balls and mudstone as contaminants. They can weaken concrete mixtures and cause structural breakdowns. To produce high-quality construction materials, large mud ball separators are essential.

- Coal Processing: The removal of clay and shale balls from coal enhances its calorific value and minimizes wear on processing equipment.

- Mineral Processing: Some ores may have sticky gangue that creates mud balls, necessitating separation prior to further beneficiation.

- Composting Facilities: Operations that compost on a large scale frequently manage organic waste that has the potential to clump together. Separators assist in refining the compost and eliminating undesirable aggregates.

- Construction & Demolition Waste: For the creation of clean, reusable aggregate, it is essential to separate soil and mud balls from recyclable concrete, brick, and asphalt.

Table of Specifications for Mud Ball Separator

| Specification | Details |

|---|---|

| Model Name | Mud Ball Separator |

| Capacity | 500 kg/hr |

| Power Requirement | 1 HP / 3-Phase |

| Drum Size | 400 mm Diameter x 1200 mm Length |

| Material of Construction | Mild Steel / Stainless Steel |

| Separation Efficiency | Up to 98% |

| Motor Brand | Crompton / Equivalent |

| Cleaning Method | Vibrating & Rotating Drum with Adjustable Airflow |

| Dust Collector Attachment | Optional |

| Overall Dimensions (LxWxH) | 1500 mm x 900 mm x 1400 mm |

| Weight | 300 kg |

| Finish | Powder Coated / Painted |

Advantage of Mud Ball Separator

- Enhanced Product Quality: The most direct advantage is a final product that is cleaner and of higher quality. By complying with strict industry standards, this enhances the value of your aggregate and its applicability across a broader spectrum of uses.

- Decreased Downtime: Mud ball separators help prevent blockages and lessen the necessity for manual cleaning of screens, conveyors, and crushers by eliminating sticky contaminants. This results in a substantial reduction in expensive operational interruptions.

- Prolonged Equipment Lifespan: Reduced clogging and stress on machines result in diminished wear on your essential processing equipment, which translates to decreased maintenance expenses and an extended operational duration for your plant.

- Enhanced Throughput and Productivity: A more seamless and efficient material flow results directly in greater production volumes and enhanced overall productivity of the plant.

- Cost Savings: Although there is an initial investment, the long-term savings from reduced maintenance, lower energy consumption (due to reduced resistance), enhanced product quality, and increased throughput far exceed the upfront cost.

- Environmental Compliance: Mud ball separators can assist operations in adhering to environmental regulations concerning discharge and material purity by effectively separating and managing contaminants.

- Proven Expertise: Our years of experience in designing and manufacturing various aggregate processing equipment have equipped us with profound technical knowledge and a comprehensive understanding of the challenges our clients encounter. Each mud ball separator is designed with care by our team of skilled engineers in order to provide optimal performance.

- Solid and Long-lasting Build: We recognize that machinery used in the aggregate sector works under challenging circumstances. For this reason, every mud ball separator from Padsons Industries is designed for durability, employing premium materials and advanced manufacturing methods. Our machines are built for durability, reducing the necessity for frequent replacements or significant repairs.

Types of Mud Ball Separators

Rotary Mud Ball Separator

- Uses a rotating drum with perforated holes.

- Grains fall through while mud balls are carried out separately.

- Ideal for medium to large-scale rice mills.

Gravity Separator Type

- Operates on the principle of specific gravity difference.

- Separates heavier grains from lighter mud balls and impurities.

- Used widely in rice, wheat, and seed processing units.

Vibratory Mud Ball Separator

- Uses vibratory motion combined with airflow to separate impurities.

- Ensures high separation accuracy.

- Suitable for delicate grains and seeds.

De-stoner Cum Mud Ball Separator

- A multi-functional machine that removes both stones and mud balls.

- Popular in integrated processing plants.

- Saves space and reduces equipment investment.

Customized Mud Ball Separators

- Tailored to meet specific capacity, grain type, and layout requirements.

- Manufactured on-demand based on client needs.

Conclusion

In the competitive realm of aggregate production, the quality of your material is directly linked to your success. Despite their small size, mud balls represent a serious danger to efficiency, quality, and profitability. Acquiring a quality mud ball separator should not be regarded as a cost; it is a tactical investment that yields returns in the form of enhanced product quality, lower operational expenses, and greater productivity. We are the best Best Mud Ball Separator Manufacturer.

Padsons Industries, a top Mud Ball Separator Manufacturer, is committed to offering you innovative solutions that fulfill and surpass your expectations. Our dedication to quality, innovation, and customer satisfaction guarantees that you receive a machine that operates reliably, even under the most challenging conditions.