Maize Sheller with Grader Manufacturer

Table of Contents

Introduction

At Padsons Industries, we specialize in crafting user-friendly manual and semi-automatic farm machinery. With a focus on simplicity and effectiveness, our equipment is designed to make farming tasks more efficient and accessible for all. Our range includes a variety of tools that cater to the diverse needs of farmers. From easy-to-use plows to hassle-free seeders, we take pride in creating machinery that simplifies the farming process. With decades of experience in the industry, we understand the challenges faced by modern-day farmers. That’s why we’re dedicated to providing practical solutions that enhance productivity and yield. Trust Padsons Industries to be your reliable partner in agriculture.

In the lush fields of rural India, where maize towers as a key crop, the journey from harvest to market is vital. Even though farmers devote great effort to growing this adaptable grain, the post-harvest task of separating kernels from cobs – called shelling – and subsequently sorting them by quality often creates a considerable bottleneck. Because this process is labor-intensive and takes a lot of time, it can result in inefficiencies, loss of product, and diminished market value.Access the Maize Sheller with Grader. We are the best Maize Sheller with Grader Supplier.

This cutting-edge agricultural implement is transforming maize processing with its potent mix of efficiency, quality oversight, and financial advantages. For farmers, processors, and even animal feed manufacturers, the investment in a high-quality Maize Sheller with Grader has transitioned from being a luxury to becoming a strategic necessity.

What is a Maize Sheller with Grader

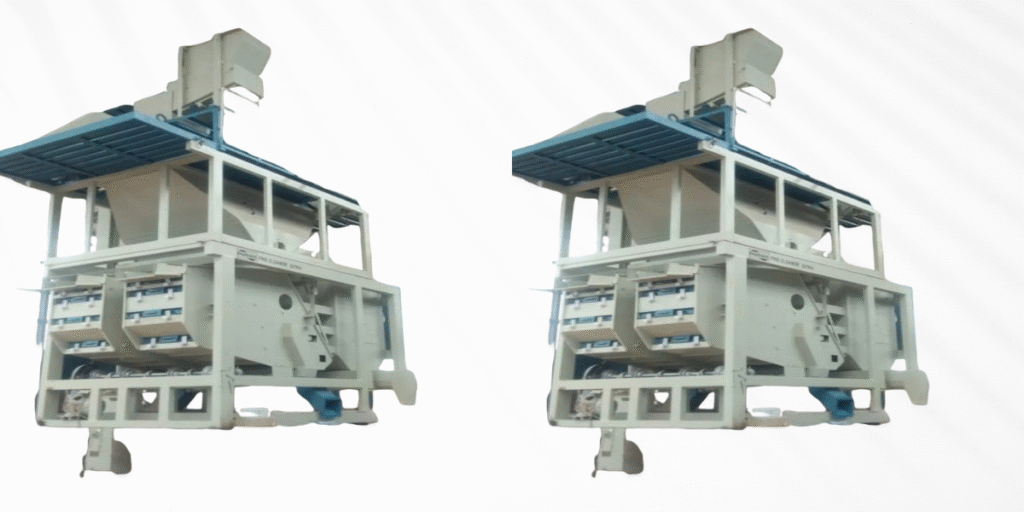

A maize sheller with grader is a multifunctional farming implement that shells maize cobs, separates the kernels from the cobs, and grades them according to size at the same time. This equipment lessens the amount of manual labor needed for traditional shelling methods and delivers uniform, high-quality kernels that are ready for market or further processing. We are the best Maize Sheller with Grader Exporter.

Why Choose Padsons Industries

- Decades of Expertise and Innovation: Founded in 1983, Padsons Industries has a rich history spanning more than four decades in the agricultural machinery industry. This vast experience results in a profound comprehension of farmers’ needs and ongoing innovation in product design and features. We are more than just producers; we are pioneers committed to the progress of agriculture.

- Sturdy and Long-Lasting Design: Our Maize Shellers with Graders are designed to endure the challenges of tough agricultural settings. We utilize high-grade mild steel (MS) and, for essential components, even SS 316, guaranteeing durability, minimal wear and tear, and reliable performance over years of use. Our machines are built to achieve the highest possible uptime while keeping breakdowns to a minimum.

- High Efficiency and Capacity: Designed for exceptional output, Padsons’ Maize Shellers with Graders are engineered to perform. Models such as the Automatic Powder Coated PADSONS Maize Sheller with Grader can reach capacities of up to 2000 kg/hr, greatly enhancing processing speed and allowing farmers to manage large harvests effortlessly. This significant capacity is essential for operations on a commercial scale.

- Gentle Shelling for Optimal Germination: We recognize how crucial it is to maintain seed integrity, particularly for maize designated for planting. The design of our shelling mechanism allows for a gentle separation of kernels from cobs through mutual rubbing, which reduces kernel breakage and maintains the germination values of delicate maize seeds. This is a crucial distinguishing factor, especially for seed processing plants.

- Effective Grader System: Our machines’ built-in grading system guarantees meticulous cleaning and accurate sorting. Our machines feature efficient blowers and multi-layered sieves to eliminate impurities and sort kernels, resulting in a clean, uniform, high-quality final product that commands superior market prices.

- Energy Efficiency: Machines designed by Padsons Industries are energy-efficient, which helps farmers reduce their operational costs. Our models generally operate on three-phase power with optimized motor power (such as 25 HP for larger units), offering a robust and cost-effective solution.

- Customization and Versatility: Our range of models allows us to offer tailored solutions that meet specific needs related to capacity, power source (electric motor, PTO driven, diesel engine), and grading precision. Our machines’ adaptability makes them appropriate for a range of farming operation scales.

- Extensive After-Sales Support: Padsons Industries does more than machine sales; it’s about establishing enduring connections. Our outstanding after-sales service featuring availability of spare parts, technical support, and maintenance advice—guarantees that your investment continues to perform at its best.

- Endorsed by Farmers Across the Country: Our enduring presence in the industry and a host of awards—including being named the “Best Agro Processing Machines Manufacturer & Exporter” and receiving various national honors—demonstrate the trust and satisfaction of our varied clientele. Our global market presence highlights the quality and reliability of our products.

Applications of a Maize Sheller Grader

- Massive Efficiency and Speed Boost: This is the primary advantage. With a good machine, the shelling and grading of tons of maize each hour becomes possible, which greatly cuts down the time needed in comparison to manual methods. This is essential for overseeing substantial harvests and adhering to market timelines.

- Considerable Labor Savings: The automation of shelling and grading processes greatly diminishes the dependence on manual labor, resulting in significant wage cost reductions and helping to ease labor shortage problems.

- Increased Yield and Minimized Grain Loss: The design of contemporary maize shellers incorporates a focus on high shelling efficiency, which guarantees that almost all kernels are removed from the cob. The grading system reduces loss even further by isolating kernels from impurities, instead of throwing away usable grain.

- Enhanced Grain Quality and Market Value: The system of integrated grading produces uniform, clean kernels devoid of impurities. This improved quality commands higher market prices, increasing the product’s appeal to buyers for consumption, animal feed, or industrial processing.

- Reduced Post-Harvest Losses: Prompt and efficient shelling and cleaning help prevent spoilage and pest infestation that can occur when maize is stored unshelled or with impurities. This has a direct impact on economic stability and food security.

- Versatility: Numerous advanced models can accommodate various maize varieties and moisture levels through adjustable settings, rendering them suitable for a range of agricultural practices.

- Robustness and Little Upkeep: Machines that are sturdy and sourced from trustworthy brands are crafted for tough agricultural use, needing little maintenance while providing extended service lives.

- Economic Viability: Though it requires an initial investment, the long-term advantages of enhanced output, lowered labor costs, improved quality, and negligible losses result in a substantial return on investment for large-scale operations. It converts the processing of maize from a bottleneck into a seamless and lucrative operation.

- Empowerment of Farmers and Cooperatives: By gaining access to this technology, large-scale farmers and farmer producer organizations (FPOs) can enhance their competitiveness, diminish their reliance on manual labor, and improve their management of post-harvest processes.

Table of Specifications Maize Sheller Grader

| Parameter | Specification |

|---|---|

| Product | Maize Sheller Grader |

| Capacity | 500 kg/hr, 1000 kg/hr, 2000 kg/hr |

| Shelling Efficiency | 98% |

| Grading System | Multi-layer sieving system |

| Number of Grading Screens | 2 / 3 / 4 (as per requirement) |

| Power Requirement | 5 HP, 7.5 HP, 10 HP (depending on model) |

| Material of Construction | MS (Mild Steel) / Stainless Steel (optional) |

| Mobility | Portable with trolley frame (optional) |

| Weight | 450 Kg / 750 Kg / 950 Kg |

| Shelling Mechanism | Rotor and concave drum type |

| Cleaning System | Integrated blower and aspirator fan |

| Voltage | 415 V, 3 Phase, 50 Hz |

| Color Finish | Powder Coated (Color Customizable) |

| Warranty | 1 Year |

Benefits of Maize Sheller Grader

- Considerable Rise in Efficiency and Throughput: Tasks that previously required days or weeks of manual work can now be completed in just a few hours. These machines are capable of processing tons of maize each hour, which results in a considerable boost to output.

- Decreased Labor Costs and Reliance: Automation lessens the requirement for considerable manual work, allowing human resources to be allocated to different duties and cutting down on operational costs. This is especially important in areas dealing with shortages of workers or increasing salaries.

- Enhanced Kernel Quality and Reduced Damage: Advanced shelling mechanisms aim to reduce kernel breakage, thereby ensuring a greater proportion of whole, undamaged kernels. These high-quality kernels are then separated through grading, which maximizes their market value.

- Enhanced Prevention of Post-Harvest Loss: By shelling maize quickly and effectively, the duration it remains in storage on the cob is minimized, thereby reducing its vulnerability to pests, mold, and rodent harm. Grading improves storage conditions by eliminating damaged kernels and foreign materials that could lead to spoilage.

- Value Addition via Grading: By separating kernels based on size and quality, farmers and processors can obtain higher prices for premium grades. It also renders maize appropriate for particular markets, including seed production (which necessitates uniform large kernels), food processing, or tailored feed formulations.

- Versatility and Adaptability: Many modern sheller-graders are designed to accommodate various maize varieties and moisture content levels, featuring adjustable settings for optimal performance.

- Higher Income and Profitability for Farmers: These machines help maize producers achieve higher net incomes by improving efficiency, minimizing losses, and adding value through grading.

- Enhanced Food Security: Reducing post-harvest losses increases the availability of maize for consumption, thereby aiding regional and national food security.

- Ease of Operation and Maintenance: Modern designs emphasize user-friendliness, featuring simpler controls and components that are easy to access for regular cleaning and maintenance, thereby minimizing downtime.

Types of Maize Shellers Graders

Tractor Operated Maize Sheller with Grader

- Powered by a tractor’s PTO shaft.

- Suitable for field operations in rural areas.

- Portable and easy to attach or detach from the tractor.

- Ideal for medium to large farms.

- High output capacity, suitable for bulk shelling.

Electric Motor Operated Maize Sheller with Grader

- Runs on electric motors, generally ranging from 5 HP to 10 HP.

- Suitable for small to medium farms or processing units near power sources.

- Low operational cost with consistent performance.

- Ideal for stationary operations in warehouses or processing centers.

Combined Multi-Crop Sheller with Grader

- Can shell and grade maize, sunflower, sorghum, and other grains.

- A versatile option for farmers dealing with multiple crops.

- Offers higher returns on investment due to multi-functionality.

- Available in both tractor-operated and motor-operated variants.

Mini Maize Sheller with Grader

- Compact in design, suitable for small farms and trial batches.

- Low maintenance and easy to operate.

- Ideal for farmers who want a cost-effective solution for limited quantities.

- Available in motor-operated models.

Heavy-Duty Maize Sheller with Grader

- Built for commercial grain processing units and large cooperative societies.

- Higher capacity ranging from 2 to 5 tons per hour.

- Equipped with heavy-duty graders, ensuring precise sorting of kernels.

- Can be customized for specific grading parameters.

Conclusion

The path of maize from cultivation to commerce is complex, and effective post-harvest processing is essential for optimizing profit margins. With its unmatched efficiency, quality, and cost savings, the Maize Sheller with Grader marks a major advancement in this process. We are the best Best Maize Sheller with Grader Manufacturer.

Padsons Industries, as a devoted manufacturer of maize shellers with graders, is leading the way in this agricultural revolution. Our dedication lies in providing Indian farmers with innovative, durable, and high-performing machinery that simplifies their tasks while significantly boosting their productivity and income.