Indented Cylinder Grader Manufacturer

Introduction

At Padsons Industries, we specialize in crafting user-friendly manual and semi-automatic farm machinery. With a focus on simplicity and effectiveness, our equipment is designed to make farming tasks more efficient and accessible for all. Our range includes a variety of tools that cater to the diverse needs of farmers. From easy-to-use plows to hassle-free seeders, we take pride in creating machinery that simplifies the farming process. With decades of experience in the industry, we understand the challenges faced by modern-day farmers. That’s why we’re dedicated to providing practical solutions that enhance productivity and yield. Trust Padsons Industries to be your reliable partner in agriculture.

Quality is crucial in the fields of agriculture and food processing. Ensuring purity and uniformity has a direct impact on market value, product safety, and ultimately, customer happiness, regardless of the size of the harvest. The Indented Cylinder Grader is one of the unsung heroes that helps achieve excellent quality, especially when it comes to grain.These clever devices are essential for sorting and classifying different grains, seeds, and even some granular materials, even if you may not be familiar with their names. They are crucial for eliminating undesired foreign objects, broken grains, and contaminants, leaving behind a clean, consistent product that is prepared for sale or further processing. We are the best Indented Cylinder Grader Supplier.

What Exactly is an Indented Cylinder Grader

Consider a big, revolving cylinder. Imagine now that thousands of neatly designed pockets or indentations cover the inside surface of the cylinder. The basic idea behind an indented cylinder grader is this. An Indented Cylinder Grader is essentially a very specialized agricultural tool used for length grading. In other words, it divides particles according to their length instead of their density or width. This is important since a lot of broken grains or contaminants are either longer or shorter than the ideal whole grains. We are the best Indented Cylinder Grader Exporter.

Why Choose Padsons Industries

- Decades of Innovation and Experience: With a long history that dates back to when it was a part of the Padgilwar Group Padsons Industries offers unmatched experience. In order to satisfy the ever-evolving demands of the agricultural sector, we continuously improve our technology and comprehend the subtleties of grain processing. We are able to design and manufacture high-performance, user-friendly machinery because to this ingrained knowledge.

- Sturdy and Dependable Design: Like all of our equipment, our indented cylinder graders are made to last. Even with constant usage, our premium-grade materials such as mild steel and stainless steel ensure outstanding durability and little wear and tear. You will get more return on your investment and have less downtime as a result.

- Unmatched Accuracy and Efficiency: The indented cylinder graders from Padsons Industries are designed to operate at their best. In order to achieve higher efficiency and throughput, our designs concentrate on optimizing the number of grading pockets. This accuracy guarantees the most accurate sorting of your grain, producing a cleaner, more consistent product.

- Advanced Cleaning Mechanisms: We use highly advanced cleaning mechanisms in our graders. Our machines efficiently remove dust, chaff, and light pollutants, leaving behind a genuinely clean product, thanks to their strong air aspiration systems and effective screen cleaning (frequently with ball cleaning systems.

- Versatility Across Crops: A variety of grains, pulses, and oilseeds are among the free-flowing materials that Padsons’ indented cylinder graders are made to handle. Because of their versatility, they are a great help to farmers and processors that work with a variety of crops.

- Easy Maintenance and User-Friendly Design: We think that cutting-edge technology should be simple to operate. Our devices provide quick and easy screen-changing mechanisms that eliminate the need for frequent user intervention and simplify maintenance.

- Dedication to Quality: At Padsons Industries, quality is a mindset that penetrates every phase of manufacturing, not just a department. We make sure every machine satisfies international standards and follow strict quality tests for all raw materials. Our numerous accolades, such as the “Rashtriya Udyog Ratna Award” and the “Best Agro Processing Machines Manufacturer attest to our constant commitment to excellence.

- Extensive Product Offering: In addition to indented cylinder graders, Padsons Industries provides a large range of agro-processing equipment, such as air classifiers, destoners, bucket elevators, gravity separators, and full millet, soybean, and wheat processing facilities. This implies that you can get comprehensive solutions for all of your grain processing requirements in one location.

- Outstanding After-Sales Support: For Padsons Industries, a machine sale marks the start of a lasting collaboration. We take great satisfaction in providing quick and effective after-sales care to keep your equipment running at its best. Our committed staff is always available to help.

- Global Reach with Local Understanding: Although we reach a global audience, we are cognizant of the unique requirements and difficulties faced by farmers and processors in India and other countries. Our advantageous location in Ghaziabad allows us to efficiently obtain raw materials and successfully serve our clients.

Applications of Indented Cylinder Grader

1. Seed Processing Industry

- Used for grading certified seeds such as wheat, barley, paddy, maize, sunflower, soybean, and many more.

- Helps in removing broken or undersized seeds from the lot.

- Essential in achieving seed uniformity and maintaining seed standards.

2. Grain Milling Industry

- Separates broken grains from whole grains to maintain quality.

- Helps in preparing grains for flour milling or further processing.

- Enhances efficiency of downstream machinery like polishers and sorters.

3. Pulse Processing Plants

- Ideal for splitting operations and for grading different varieties of pulses like lentils, chickpeas, and peas.

- Ensures that only high-quality pulses are packed and marketed.

4. Malting and Brewing Industry

- Used in grading malted barley to ensure uniformity in the brewing process.

- Helps maintain consistent brewing quality and efficiency.

5. Spice and Herb Processing

- Applied in separating stem pieces and oversized parts from seeds and herbs like coriander, cumin, and fennel.

6. Feed and Oilseed Industry

- Used for grading oilseeds like sunflower, soybean, mustard, and groundnut before pressing.

- Improves oil extraction efficiency and quality.

Table Specifications Indented Cylinder Grader

| Model | Capacity (TPH) | Motor Power (HP) | Cylinder Diameter (mm) | Length (mm) | No. of Cylinders | Material |

|---|---|---|---|---|---|---|

| Padsons-ICG-1 | 1 – 1.5 | 1 | 400 | 2000 | 1 | Mild Steel / SS304 |

| Padsons-ICG-2 | 2 – 3 | 2 | 500 | 2200 | 2 | Mild Steel / SS304 |

| Padsons-ICG-3 | 3 – 5 | 3 | 600 | 2500 | 3 | Mild Steel / SS304 |

| Padsons-ICG-4 | 5 – 7 | 5 | 800 | 3000 | 4 | Mild Steel / SS304 |

Benefits of Indented Cylinder Grader

- The most evident and important advantage is superior purity and quality. The final product meets a far higher degree of purity by eliminating extraneous debris including cracked, shriveled, or undesired kernels. For your clients, be they bakers, brewers, or consumers, this directly translates into higher quality.

- Increased Yield and Decreased Waste: You can increase the amount of high-quality, usable grain by efficiently separating out the contaminants. This directly improves your bottom line by decreasing waste and increasing the yield from your raw materials.

- Increased Processing Efficiency: Grain that has been cleaned passes more easily through the milling, drying, and packing phases of the processing process. In the end, this results in more effective operations overall by lowering obstructions and wear and strain on other equipment.

- Fulfilling Strict Quality criteria: Grain purity is subject to strict quality control criteria in several businesses. An essential instrument for fulfilling these specifications and preventing expensive rejections or fines is an indented cylinder grader.

- Better Product Consistency: You can guarantee a consistent product by continuously eliminating unwanted components. Customer happiness and brand reputation depend heavily on this consistency.

- Versatility: Indented cylinder graders are extremely adaptable for a range of applications since they may be set up with indentations of varying sizes to separate a large variety of grains and seeds. These machines can be customized to meet your unique demands for barley, corn, rice, and wheat.

- Long-Term Cost-Effectiveness: Although a one-time investment is necessary, the long-term advantages of decreased waste, increased yields, and enhanced product quality greatly exceed the expense. They are designed to last and function dependably, guaranteeing a healthy return on investment.

- Improved Product Purity and Quality: This is possibly the biggest benefit. The overall purity and quality of your finished product are greatly increased by eliminating any small, large, broken, or foreign particles. This results in healthier crops and higher germination rates for seeds. It guarantees consistency and satisfies strict quality criteria for food goods.

- Enhanced Throughput and Efficiency: When compared to human sorting, automated grading significantly accelerates processing. Because of their great capacity, modern indented cylinder graders enable you to process huge amounts of material effectively, increasing throughput and lowering labor expenses.

Types of Indented Cylinder Graders

1. Single Cylinder Indented Grader

- This type of grader uses a single cylinder with indentations to separate grains of different lengths. It is ideal for small-scale operations or single-product grading.

Uses:

- Separation of broken rice from whole rice

- Removal of weed seeds from wheat or barley

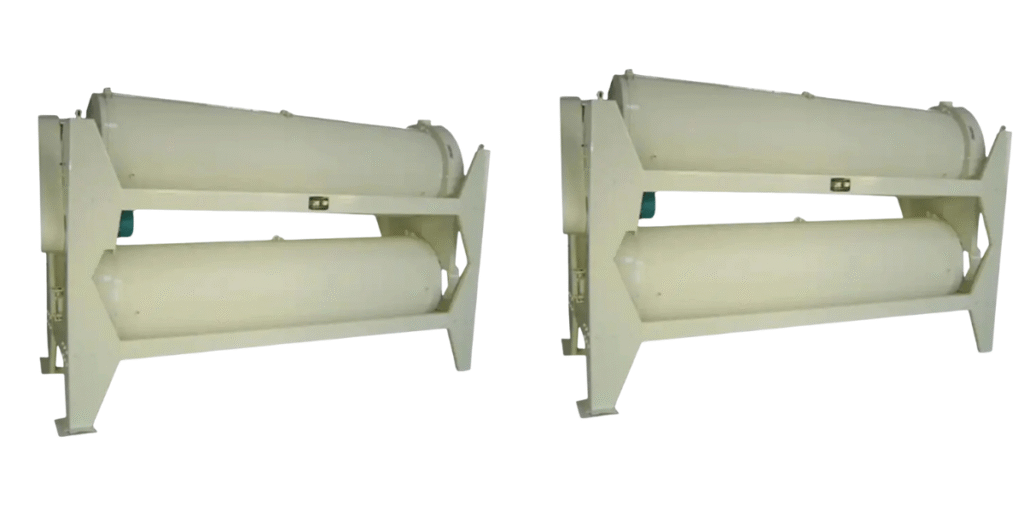

2. Double Cylinder Indented Grader

- This type includes two cylinders arranged in series. The first cylinder separates short grains or impurities, and the second cylinder refines the output further by separating long impurities.

Uses:

- Accurate two-stage separation in one pass

- Efficient grading of wheat, paddy, rice, soybeans, lentils, etc.

3. Modular Indented Cylinder Grader

- A modular design allows multiple cylinders to be combined, offering high capacity and flexibility. These graders are ideal for large-scale industrial use.

Features:

- Higher throughput

- Easy maintenance and replacement of individual cylinders

- Flexible for future expansion

4. Horizontal and Vertical Indented Graders

- Padsons also offers customized solutions based on layout preferences — either horizontal or vertical orientation.

Benefits:

- Space-saving vertical models for compact units

- Easy-to-integrate horizontal models for large installations

Conclusion

In today’s agricultural and grain processing environment, the indented cylinder grader is an essential piece of machinery that allows for unmatched length-based separation precision. Purchasing a top-notch indented cylinder grader is more than just purchasing a piece of equipment; it’s an investment in improved product quality, more productivity, and eventually, higher business profitability. We are the best Best Indented Cylinder Grader Manufacturer.

Our goal at Padsons Industries is to equip the agricultural industry with dependable and innovative machinery. Our indented cylinder graders are made to satisfy the changing needs of the market, enabling you to produce better outcomes and keep your competitive advantage. Select Padsons Industries, your reliable partner for a prosperous future, when accuracy counts.