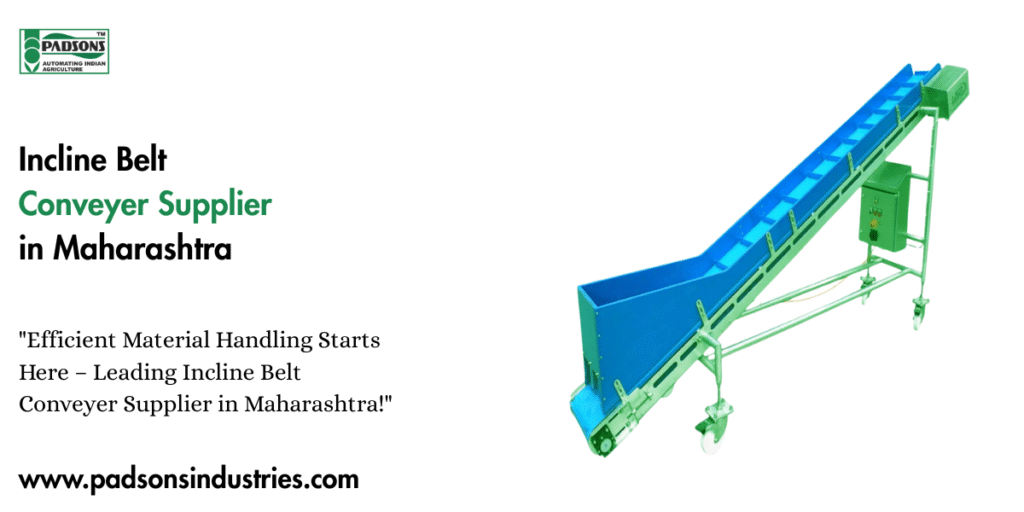

Incline Belt Conveyer Supplier in Maharashtra

Introduction

At Padsons Industries, we specialize in crafting user-friendly manual and semi-automatic farm machinery. With a focus on simplicity and effectiveness, our equipment is designed to make farming tasks more efficient and accessible for all. Our range includes a variety of tools that cater to the diverse needs of farmers. From easy-to-use plows to hassle-free seeders, we take pride in creating machinery that simplifies the farming process. With decades of experience in the industry, we understand the challenges faced by modern-day farmers. That’s why we’re dedicated to providing practical solutions that enhance productivity and yield. Trust Padsons Industries to be your reliable partner in agriculture.

Productivity and efficiency are essential for being competitive in the fast-paced industrial environment of today. A belt conveyor system is one of the most important tools used by industry to do this. Among these, the incline belt conveyor is essential for effectively transferring products between levels. Padsons Industries is a prominent supplier of high-quality, long-lasting, and reasonably priced conveyor solutions if you’re searching for a reliable incline belt conveyor supplier in Maharashtra. We are the best Incline Belt Conveyer Manufacturer.

Efficiency and dependability are essential for seamless operations in the fast-paced industrial environment of today. Among the many varieties of conveyors, incline belt conveyors have become essential in sectors including manufacturing, mining, packing, and logistics. Conveyors are essential for optimizing material handling procedures. Padsons Industries is your go-to partner if you’re looking for a trustworthy incline belt conveyor supplier in Maharashtra. They provide premium, long-lasting, and reasonably priced conveyor solutions.

What is an Incline Belt Conveyor

One kind of conveyor system used to transfer materials from one level to another at an angle is the incline belt conveyor. In contrast to horizontal conveyors, which only move objects across a level surface, incline conveyors provide the safe lifting or lowering of products. They are extensively utilized in the bulk material handling, production line, and warehouse industries. We are the best Incline Belt Conveyer Exporter.

Why Choose Padsons Industries

- Uncompromising Commitment to Quality We believe in building conveyors that last. At our manufacturing facility, we use premium-grade materials and advanced fabrication techniques. Every weld is inspected, every alignment is checked, and every component, from the strongest frames to the most efficient motors, is selected for durability and performance. This means you get a conveyor that minimizes downtime and maximizes your return on investment.

- Deep-Rooted Engineering Prowess At our core, we are problem-solvers. Our team of experienced engineers doesn’t just take orders; they consult with you. We analyze the material you need to move—be it powdery, granular, packaged, or fragile—and design a conveyor with the perfect belt type (cleated, rough top, food-grade), the optimal incline angle, and the right power to handle your load without fail.

- Customization is Our Standard We understand that no two facilities are the same. That’s why we offer a high degree of customization. Need a specific length, width, or height? Require special belts or guarding? We can build it. We provide solutions that fit your unique workflow and spatial constraints, not the other way around.

- A Comprehensive Product Range While our focus here is on incline belt conveyors, we offer a wide array of material handling solutions. This holistic approach means we can advise you on the best solution for your entire workflow, not just one part of it.

- Our Commitment is Long-Term Our relationship with you doesn’t end at the sale. Padsons Industries is renowned for its stellar after-sales service. From installation and commissioning to routine maintenance and readily available spare parts, our support team is always on standby to ensure your operations run smoothly, forever.

- Custom-Engineered Solutions: We understand that off-the-shelf solutions rarely fit all. At Padsons Industries, we pride ourselves on our ability to design and manufacture bespoke incline belt conveyors tailored precisely to your specific operational requirements, space constraints, and material characteristics. Our engineering team works closely with you to understand your needs and deliver a solution that optimizes your workflow.

- Comprehensive Product Range: While incline belt conveyors are a specialty, Padsons Industries offers a wider array of agro-processing and material handling machinery. This breadth of expertise means we can provide integrated solutions, ensuring seamless compatibility and efficiency across your entire facility. Our range includes Seed Graders, Destoners, Bucket Elevators, Seed Treater Machines, and more, all designed with the same commitment to excellence.

- Awards and Recognition: Our dedication to innovation and quality has been consistently recognized. From the “Best Agro Processing Machines Manufacturer & Exporter” award from D.I.C. Maharashtra to the “Export Award” from the Industry Ministry of the Government of Maharashtra, and the “National Award” from the Jagtic Marathi Chamber of Commerce and Industry, these accolades reflect our leadership and contribution to the industry.

- Customer-Focused Strategy and Post-Sales Service: For Padsons Industries, the sale of a machine marks the start of an enduring collaboration. We are committed to establishing lasting relationships with our clients through timely, effective, and thorough after-sales support. Our devoted support team guarantees rapid access to spare parts, technical help, and maintenance services, reducing downtime and optimizing your investment returns. We seek out customer feedback and make valid adjustments to continuously improve our products and services.

- Innovation for the Future of Agriculture and Industry: We are constantly striving to push the boundaries of what’s possible. Our passion for exploring new areas and transforming challenges into opportunities drives our continuous innovation. We integrate modern technologies and best practices to ensure our incline belt conveyors, and all our machinery, are at the forefront of efficiency and sustainability.

Applications of Incline Belt Conveyors

1. Food Processing Industry

- Incline belt conveyors are crucial in food processing plants, helping move products like grains, fruits, vegetables, and packaged goods between different processing stages. Special food-grade belts are used to ensure hygiene and safety.

2. Mining and Mineral Handling

- Mining operations require robust conveyors to transport ores, coal, and minerals from lower levels to processing units. Incline belt conveyors offer a reliable solution to move heavy loads over challenging elevations efficiently.

3. Cement and Construction Industry

- In cement plants, raw materials such as limestone, clinker, and sand need to be transported between crushers, mixers, and storage silos. Incline belt conveyors streamline these processes, reducing manual labor and improving safety.

4. Packaging and Manufacturing Units

- In manufacturing industries, conveyors facilitate smooth movement of products from one assembly line to another. Incline conveyors save space and help in creating multi-level production layouts.

5. Agriculture and Food Grain Handling

- Incline belt conveyors are used in agriculture for transporting grains, seeds, fertilizers, and other materials from trucks to silos or storage bins. This significantly reduces handling time and labor costs.

6. Warehousing and Logistics

- Warehouses with multiple levels benefit from incline belt conveyors, allowing seamless movement of goods from storage areas to dispatch zones, thereby optimizing workflow.

7. Automotive and Manufacturing Industry

- Incline belt conveyors are also used in assembly lines for transporting automotive parts, components, and heavy machinery. They streamline production and reduce manual handling of bulky items.

8. Warehousing and Logistics

- In warehouses and logistics centers, these conveyors help move goods efficiently between floors, storage racks, or loading docks. This improves the speed of operations and reduces dependency on forklifts or manual labor.

Table of Specification Incline Belt Conveyors

| Specification | Details |

|---|---|

| Material | Incline Belt Conveyors |

| Belt Width | 300 mm – 1200 mm |

| Belt Length | 2 meters – 15 meters |

| Incline Angle | 0° – 45° (customizable) |

| Frame Material | Stainless Steel / Mild Steel |

| Motor Type | AC Motor, Variable Speed |

| Capacity | 500 – 5000 kg/hr |

| Application | Food, Pharmaceutical, Manufacturing, Packaging |

Benefits of Incline Belt Conveyors

- Engineered for Your Exact Needs: We understand that no two facilities are the same. A one-size-fits-all approach doesn’t work. Our team of experts will work with you to understand your material, incline angle, throughput requirements, and space constraints. We then design and manufacture a conveyor that is a perfect fit for your operation, ensuring optimal performance from day one.

- Uncompromising Build Quality & Durability: An incline conveyor faces constant stress and strain. At Padsons, we use only the highest quality materials—sturdy MS or SS frames, industrial-grade belts with appropriate cleats or profiles, and powerful, energy-efficient motors. This commitment to quality means our conveyors are built to last, withstand harsh industrial environments, and require minimal maintenance, giving you a superior return on your investment.

- Enhanced Safety Features: Safety is our top priority. Our incline belt conveyors come equipped with essential safety features to protect your staff and your goods. These can include side guards to prevent items from falling, emergency stop cords along the entire length, and anti-rollback mechanisms to ensure materials stay securely in place, even during an unexpected power halt.

- Smooth & Reliable Operation: A noisy, jerky conveyor disrupts the entire workplace. Padsons’ conveyors are engineered for smooth and quiet operation. The precision engineering ensures minimal vibration and noise, creating a better working environment and reducing wear and tear on the system itself, leading to a longer lifespan.

- Expert Support, From Start to Finish: Our relationship with you doesn’t end with the sale. We offer comprehensive support, including professional installation by our trained team to ensure everything is set up correctly. We also provide readily available spare parts and responsive maintenance services to keep your operations running smoothly for years to come. We are your reliable partner, not just a vendor.

- Maximizes Space: Instead of using valuable floor space for ramps or relying on manual labor, you can use the vertical space above. This leads to a more organized and spacious facility.

- Boosts Efficiency & Productivity: Automating the process of moving materials upwards is exponentially faster and less exhausting than having workers carry loads up stairs or using forklifts for every small task.

- Reduces Labor Costs & Manual Handling: By automating vertical transport, you free up your workforce for more skilled tasks. This also significantly reduces the risk of injuries from lifting heavy items, leading to a safer workplace.

- Improves Workflow: An incline conveyor creates a seamless, continuous flow between different stages of your production or dispatch process, eliminating bottlenecks and ensuring a smooth operation from start to finish.

- Versatility: These conveyors can handle a wide range of materials, from packaged goods in a warehouse to agricultural produce in a food plant, making them a versatile solution for many industries in Maharashtra.

Types of Incline Belt Conveyors

1. Flat Belt Incline Conveyor

- This type is widely used in industries where lightweight items are transported. It features a flat belt that moves items upward or downward, making it suitable for boxed goods, food products, and small packages.

2. Modular Belt Incline Conveyor

- A modular belt conveyor uses interlocking plastic belts instead of traditional rubber belts. It is ideal for handling items that require flexibility, easy cleaning, and smooth transfer, such as food and pharmaceutical products.

3. Cleated Belt Conveyor

- Cleated incline conveyors have vertical cleats or ridges on the belt surface. These cleats prevent materials from slipping backward, making it perfect for transporting loose, granular, or bulk materials like grains, sand, and powders.

4. Curved Incline Conveyor

- This type is designed for factories or plants with limited space. It allows materials to move upward while following a curved path, efficiently utilizing floor space without compromising performance.

5. Custom Incline Conveyors

- For industries with unique requirements, Padsons Industries offers custom-designed conveyors. These are tailored for specific angles, lengths, load capacities, and special materials, ensuring perfect integration into your production line.

Conclusion

Incline belt conveyors are more than simply a convenience for Maharashtra’s businesses; they are essential for effective material handling. You may guarantee seamless operations, higher productivity, and long-term cost savings by selecting a trustworthy provider. We are the Best Incline Belt Conveyer Supplier.

Delivering premium, long-lasting, and personalized incline belt conveyors is our area of expertise at [Your Company Name]. We offer complete solutions for companies in Pune, Mumbai, Nashik, Nagpur, and elsewhere, from consulting to installation and upkeep. Join together with us to improve your industrial operations with dependable, safe, and effective conveyor systems.