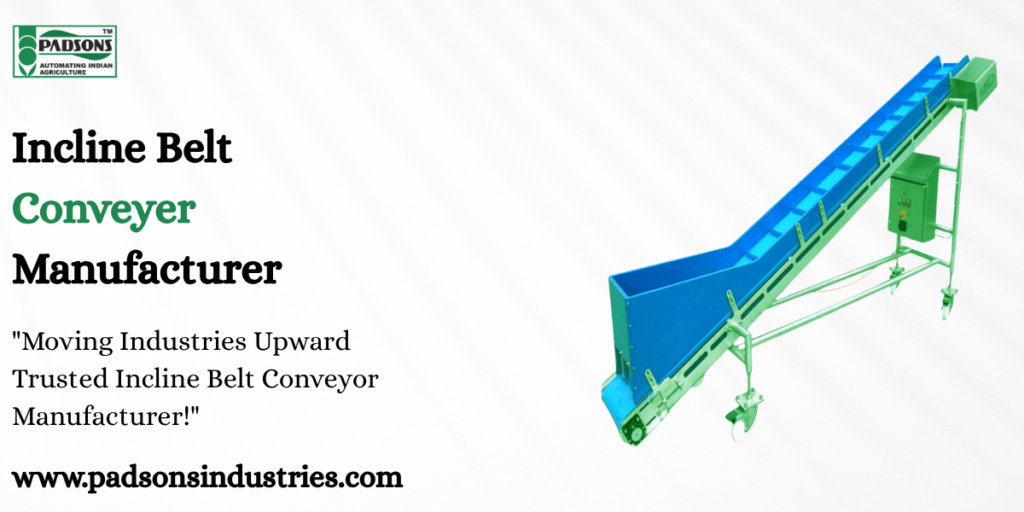

Incline Belt Conveyer Manufacturer

Introduction

At Padsons Industries, we specialize in crafting user-friendly manual and semi-automatic farm machinery. With a focus on simplicity and effectiveness, our equipment is designed to make farming tasks more efficient and accessible for all. Our range includes a variety of tools that cater to the diverse needs of farmers. From easy-to-use plows to hassle-free seeders, we take pride in creating machinery that simplifies the farming process. With decades of experience in the industry, we understand the challenges faced by modern-day farmers. That’s why we’re dedicated to providing practical solutions that enhance productivity and yield. Trust Padsons Industries to be your reliable partner in agriculture.

In the ever-changing environment of contemporary industry, the transport of materials is essential for production. Conveying systems that are dependable and efficient are essential for transporting raw materials into a facility and finished products out of it. The Incline Belt Conveyor is a true workhorse among the various material handling solutions, allowing businesses to transport goods seamlessly between different elevations, optimize space, and greatly enhance productivity.This detailed article investigates the realm of incline belt conveyors, examining their core principles, various uses, complexities of production, and the importance of selecting the right manufacturer—such as Padsons Industries—for sustained operational success. We are the best Incline Belt Conveyer Supplier.

What is an Incline Belt Conveyor

Essentially, an incline belt conveyor is a mechanical system intended to transport materials up or down along a slope. Unlike horizontal conveyors that move items along a flat surface, incline conveyors utilize gravity and specially designed belts to enable vertical or nearly vertical transport. Though it may seem simple, this mechanism opens up a realm of possibilities for industries aiming to optimize their operations. We are the best Incline Belt Conveyer Exporter.

Why Choose Padsons Industries

- Decades of Expertise and Proven Track Record: With over half a century of experience, Padsons Industries has an unparalleled understanding of material handling challenges across various sectors. Our extensive portfolio of successful installations and satisfied clients speaks volumes about our reliability and expertise. We are not just a manufacturer; we are seasoned problem-solvers.

- Unwavering Commitment to Quality: Quality is the cornerstone of everything we do. From the selection of premium raw materials to stringent quality checks at every stage of manufacturing, we adhere to the highest international standards. Our ISO 9001:2000 certification is a testament to our dedication to delivering world-class products. We employ robust designs, precision engineering, and durable components to ensure our incline belt conveyors operate flawlessly for years to come.

- Custom-Engineered Solutions: We understand that off-the-shelf solutions rarely fit all. At Padsons Industries, we pride ourselves on our ability to design and manufacture bespoke incline belt conveyors tailored precisely to your specific operational requirements, space constraints, and material characteristics. Our engineering team works closely with you to understand your needs and deliver a solution that optimizes your workflow.

- Comprehensive Product Range: While incline belt conveyors are a specialty, Padsons Industries offers a wider array of agro-processing and material handling machinery. This breadth of expertise means we can provide integrated solutions, ensuring seamless compatibility and efficiency across your entire facility. Our range includes Seed Graders, Destoners, Bucket Elevators, Seed Treater Machines, and more, all designed with the same commitment to excellence.

- Awards and Recognition: Our dedication to innovation and quality has been consistently recognized. From the “Best Agro Processing Machines Manufacturer & Exporter” award from D.I.C. Maharashtra to the “Export Award” from the Industry Ministry of the Government of Maharashtra, and the “National Award” from the Jagtic Marathi Chamber of Commerce and Industry, these accolades reflect our leadership and contribution to the industry.

- Customer-Focused Strategy and Post-Sales Service: For Padsons Industries, the sale of a machine marks the start of an enduring collaboration. We are committed to establishing lasting relationships with our clients through timely, effective, and thorough after-sales support. Our devoted support team guarantees rapid access to spare parts, technical help, and maintenance services, reducing downtime and optimizing your investment returns. We seek out customer feedback and make valid adjustments to continuously improve our products and services.

- Innovation for the Future of Agriculture and Industry: We are constantly striving to push the boundaries of what’s possible. Our passion for exploring new areas and transforming challenges into opportunities drives our continuous innovation. We integrate modern technologies and best practices to ensure our incline belt conveyors, and all our machinery, are at the forefront of efficiency and sustainability.

Applications of Incline Belt Conveyors

- Elevating Efficiency and Throughput: At the heart of any large industrial facility is the continuous flow of materials. Incline belt conveyors are engineered for high throughput, capable of transporting vast volumes of material consistently and predictably. This eliminates bottlenecks, minimizes interruptions, and ensures a steady material flow, even during peak operational hours. For industries dealing with bulk materials like grains, minerals, or processed goods, this translates directly to increased production and reduced downtime.

- Optimizing Space Utilization: In warehouses, factories, and processing plants, space is often a premium. Incline conveyors effectively utilize vertical space, allowing materials to be transported upwards or downwards without consuming valuable horizontal floor area. This is a game-changer for facilities with limited footprints, enabling more efficient layouts and freeing up space for other critical operations. Steep incline conveyors, with their specialized belts and configurations, can achieve even greater angles, significantly reducing the overall conveyor length and further optimizing space.

- Enhancing Safety and Reducing Manual Labor: The manual lifting and transporting of heavy or bulky materials pose significant risks of workplace injuries. Incline belt conveyors automate this process entirely, eliminating the need for human intervention in vertical material movement. This drastically reduces the risk of strains, sprains, and accidents, creating a safer working environment for employees and allowing them to focus on more complex, value-added tasks.

- Versatility in Material Handling: From fine powders and granular materials to large, irregularly shaped items, incline belt conveyors are remarkably versatile. The choice of belt material (e.g., PVC, rubber), the inclusion of cleats or sidewalls, and adjustable belt speeds allow these conveyors to be tailored to the specific characteristics of the material being transported, preventing slippage and ensuring secure movement. This adaptability makes them suitable for diverse sectors, from agriculture and food processing to mining and construction.

- Durability and Low Maintenance: Designed for demanding industrial environments, heavy-duty incline belt conveyors are built with robust materials, ensuring a long service life and requiring minimal maintenance. This durability translates into lower operational costs and reduced downtime, a crucial factor for large-scale operations where any interruption can have significant financial repercussions.

Table of Specifications Incline Belt Conveyors.

| Parameter | Specification |

|---|---|

| Conveyor Type | Incline Belt Conveyor |

| Belt Material | PVC, Rubber, PU, or Custom |

| Belt Width Range | 300 mm to 2000 mm |

| Conveyor Length Range | 2 meters to 50 meters (or customized) |

| Incline Angle | Up to 45° (as per material requirement) |

| Load Capacity | 50 kg/meter to 500 kg/meter |

| Speed Range | 5 m/min to 50 m/min |

| Frame Construction | Mild Steel (MS), Stainless Steel (SS), Aluminium |

| Drive Type | Electric Motor with Gearbox |

| Cleats/Side Guards | Optional (depending on product type and inclination) |

| Portability | Fixed / Mobile (as per customer requirement) |

| Application Sectors | Warehousing, Packaging, Mining, Food Processing, etc. |

Types of Incline Belt Conveyors

Cleated Incline Belt Conveyor

- This type features cleats (raised sections) on the belt surface to prevent materials from sliding back when moving upward at steeper angles. Perfect for handling loose or bulk materials like grains, chemicals, or packaged products.

Key Features:

- Available in PVC, PU, and rubber belts

- Cleat heights and spacing as per requirement

- Supports steep inclinations up to 60°

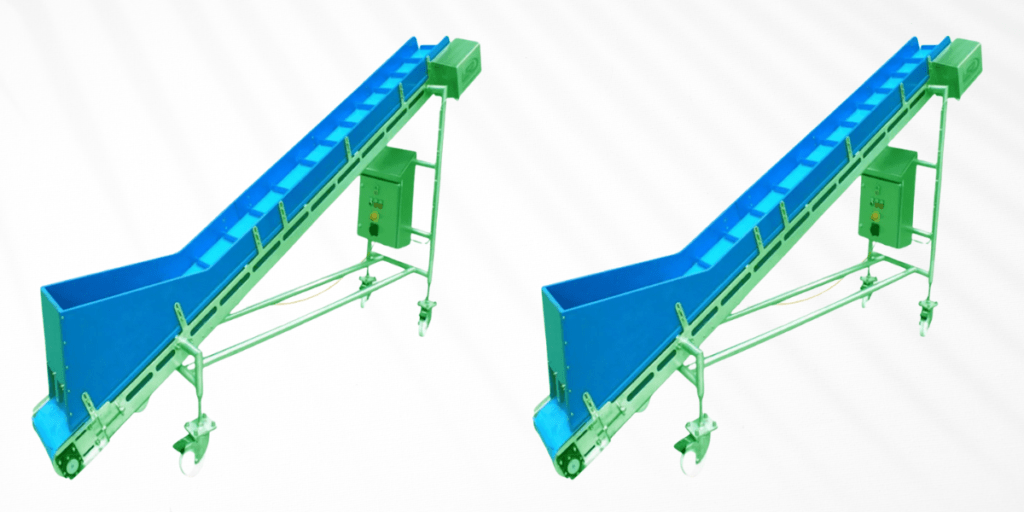

Portable Incline Belt Conveyor

- Lightweight, movable conveyors equipped with wheels for easy portability. Ideal for small warehouses, loading docks, or temporary workstations.

Key Features:

- Adjustable incline angles

- Compact and space-saving

- Quick installation and repositioning

Modular Incline Belt Conveyor

- Uses modular plastic belts for enhanced flexibility and easy maintenance. Suitable for industries where frequent cleaning or belt replacement is necessary.

Key Features:

- High resistance to chemicals and moisture

- Quick disassembly for sanitation

- Suitable for food, pharmaceutical, and chemical industries

Heavy-Duty Incline Belt Conveyor

- Designed to handle high-capacity loads and heavy materials such as stone, coal, or metal components.

Key Features:

- Robust steel construction

- Heavy-duty motors and reinforced belts

- Optional side guards and feeding hoppers

Z-Type Incline Belt Conveyor

- Features a unique Z-shaped configuration with horizontal-incline-horizontal sections. Suitable for confined spaces where both vertical and horizontal conveying are required.

Key Features:

- Compact, space-efficient design

- Ideal for conveying fragile or small parts

- Can be integrated into existing systems

Conclusion

In an environment where operational efficiency and cost-effectiveness are essential distinguishing factors, the incline belt conveyor serves as a fundamental component of effective material handling. Because of its capability to transfer materials across varying heights without interruption, make the best use of space, and improve safety, it is a vital resource for companies in numerous sectors. We are rthe best Best Incline Belt Conveyer Manufacturer.

Selecting the appropriate Incline Belt Conveyor Manufacturer is crucial for accessing these advantages. With its decades of expertise, steadfast dedication to quality, precision engineering, and commitment to customer satisfaction, Padsons Industries is the perfect partner for you. We do more than just produce conveyors; we design solutions that enhance your operations, simplify your processes, and have a direct positive impact on your profits.