Cotton Seed Delinting Plant Manufacturer

Introduction

At Padsons Industries, we specialize in crafting user-friendly manual and semi-automatic farm machinery. With a focus on simplicity and effectiveness, our equipment is designed to make farming tasks more efficient and accessible for all. Our range includes a variety of tools that cater to the diverse needs of farmers. From easy-to-use plows to hassle-free seeders, we take pride in creating machinery that simplifies the farming process. With decades of experience in the industry, we understand the challenges faced by modern-day farmers. That’s why we’re dedicated to providing practical solutions that enhance productivity and yield. Trust Padsons Industries to be your reliable partner in agriculture.

Cotton is more than simply a crop; it is the basis for textiles, a source of income for millions of people, and an important part of the world economy. But it all begins with a single, little seed before a delicate boll of cotton can be turned into a cozy t-shirt. And a process known as delinting frequently makes it more simpler and more successful for that seed to grow into a robust, fruitful plant. We are the best Cotton Seed Delinting Plant Supplier.

Cotton seeds have a fuzzy covering of small fibers called linters, as any farmer, seed processor, or other person working in the agricultural sector is aware. Despite being a normal component of the seed, these linters pose a number of serious difficulties. They can contain pests and illnesses, block planting equipment, and cause seeds to stick together. A Cotton Seed Delinting Plant is a ground-breaking device that turns these fuzzy seeds into kernels that are smooth and ready to plant.

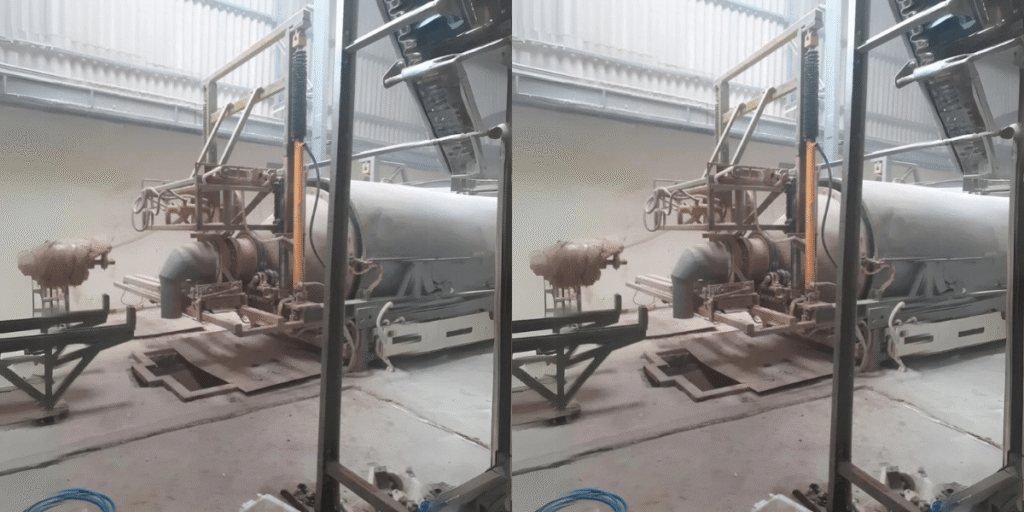

What Exactly is a Cotton Seed Delinting Plant

A cotton seed delinting plant is essentially a specialist establishment with equipment made to extract the fuzzy lint from cotton seeds. This procedure, called delinting, is an essential part of contemporary, highly productive cotton production. The plant prepares the seeds for better planting, better germination, and healthier growth by removing the lint.Although there are a few primary methods for delinting cotton seeds, the most popular and successful ones use a mechanical or chemical procedure.

Mechanical delinting involves manually rubbing the lint off the seeds using friction and specialized equipment. The lint is dissolved by chemical delinting, usually with sulfuric acid, which preserves the seed coat. To get the best quality outcomes, the most sophisticated plants frequently combine several techniques. We are the best Cotton Seed Delinting Plant Exporter.

Why Choose Padsons Industries

- Vast Experience and Expertise: Padsons Industries has years of experience in the field and has developed extensive knowledge and expertise in the design and construction of cotton processing equipment, including delinting machines. Our team of expert engineers and technicians understands the complexity of the delinting process and can provide tailored solutions to match your individual requirements.

- Tailored Solutions: We understand that every cotton processing plant has different requirements and sizes. With consideration for your budget, processing capacity, and particular output needs, Padsons Industries provides specialized delinting plant solutions. We collaborate closely with our customers to create and construct plants that precisely suit their unique requirements.

- Cutting-Edge Innovation and Technology: Padsons Industries is dedicated to remaining at the forefront of innovations in cotton processing technology. Our delinting facilities use the newest features and advancements to guarantee maximum effectiveness, energy efficiency, and user-friendliness. In order to enhance our goods and offer our clients state-of-the-art solutions, we consistently engage in research and development.

- Excellent Quality and Dependability: Our dedication to quality is unshakeable. In order to ensure sturdy construction, dependable operation, and an extended service life, Padsons Industries manufactures its delinting plants using premium materials and components. You will receive a plant that satisfies the highest industry requirements thanks to our strict quality control procedures at every stage of production.

- Energy Efficiency: Energy efficiency is a crucial factor in the ecologically conscious society of today. In order to help you lower your operating expenses and environmental impact, Padsons Industries designed its delinting plants with an emphasis on lowering energy use.

- Ease of Maintenance and Operation: We recognize the value of equipment that is easy to use. Our delinting plants are made to be simple to use and require little upkeep, which minimizes downtime and increases output. We also give your staff thorough training to guarantee the plant runs smoothly and effectively.

- Extensive After-Sales Support: We are dedicated to our customers even after the sale. Complete after-sales service is offered by Padsons Industries, which includes timely technical support, operator training, installation help, and spare part availability. We’re always available to make sure your delinting plant runs as efficiently as possible.

- Competitive Pricing: Padsons Industries offers competitive pricing for our delinting plants, giving you great value for your investment even though we place a high priority on quality and performance.

- Made in India Benefit: Padsons Industries, a manufacturer situated in Ghaziabad, Uttar Pradesh, India, provides the benefit of locally produced equipment with easily accessible replacement parts and timely service. We are honored to promote the expansion of the domestic cotton processing sector and to contribute to the campaign.

Applications of Cotton Seed Delinting Plant

1. Seed Processing Units

- Companies involved in producing certified seeds use delinting plants to ensure their seeds are clean and ready for sowing.

2. Cotton Ginning Mills

- Ginning mills use delinting plants as a part of their post-ginning processes to add value to their cottonseed by preparing it for oil extraction or resale as sowing seed.

3. Agro-Cooperatives and Farmer Groups

- Large cooperative societies and farmer collectives use these plants to improve seed quality for their members, reducing dependency on expensive commercial seeds.

4. Oil Extraction Industries

- Delinted seeds are preferred for oil extraction processes because they give better output with fewer impurities.

5. Research Institutes

- Agricultural universities and research stations use delinting machines to prepare seeds for experimental trials, ensuring purity and consistency.

7. Animal Feed and Cattle Fodder

- Cotton seeds are also crushed to make cottonseed cake, a protein-rich cattle feed. Delinted seeds help improve the quality of animal feed and make it more nutritious.

8. Agricultural Institutes and Seed Research

- Research labs and agricultural institutes need clean, disease-free seeds for testing and breeding purposes. A delinting plant ensures the seeds meet scientific standards.

Table Specifications Cotton Seed Delinting Plant

| Specification | Details |

|---|---|

| Product | Cotton Seed Delinting Plant |

| Type | Batch / Continuous |

| Material of Construction | SS304 / MS with Epoxy Coating |

| Capacity | 1 TPH / 2 TPH / 5 TPH |

| Delinting Method | Acid / Mechanical |

| Chemical Dosing System | Automatic with Safety Control |

| Heating System | Electric / Steam-based |

| Exhaust System | Included with Scrubber Unit |

| Control Panel | PLC / Manual Options |

| Power Requirement | 7.5 HP – 25 HP (Depending on model) |

| Dimensions | Customized |

| Safety Features | Acid Neutralization, Alarm System |

| After-Sales Service | Available across India & exports |

The Benefits of Cotton Seed Delinting Plant

- Better Germination and Seedling Vigor: A cotton seed’s fuzzy lint may serve as a barrier, keeping it from collecting water and promoting rapid, uniform germination. Conversely, seeds that are delinted are better able to absorb water, which promotes quicker and more reliable germination. As a result, the plant has a better start and is more resistant to illnesses and pests.

- Decreased Seed Rate and Simpler Planting: The fuzz causes seeds to group together, making precise sowing challenging. In order to guarantee a good stand, farmers frequently need to use more seeds than are necessary. Modern gear can plant seeds more precisely since delinted seeds are smooth and flow smoothly. Farmers save money and less seed waste as a result.

- Improved Seed Treatment: Because delinted seeds have a clean surface, seed treatments like fungicides and insecticides can be applied more effectively and consistently. This gives the young plant better protection, which results in a stronger crop with a larger yield.

- Control of Pests and Diseases: Pathogens and insect eggs may be present in the lint on fuzzy seeds. Delinting gives the crop a cleaner start by eliminating the fuzz, which helps to eliminate or kill these possible dangers.

- Improved Oil and Meal Processing: The seeds are cleaner and simpler to process after delinting, making it possible to obtain lucrative cottonseed oil and protein-rich meal—two essential components of animal feed. When refined for use in a variety of industrial applications, the extracted lint itself can also be a valuable byproduct.

- Eco-Friendly Developments: Contemporary delinting facilities are built with the environment in mind. In addition to reducing pollution, they occasionally have the ability to turn unused linter powder into a valuable commodity. Compared to earlier, riskier techniques, this is a huge improvement.

- Better Germination and Yield: Seeds that are clean and delinted make better contact with the soil, which promotes quicker and more consistent germination. This maximizes your potential production by guaranteeing a robust and healthy plant stand.

- Planting uniformly: Delinted seeds move easily through planters, enabling accurate crop spacing and flawless consistency. By doing this, garbage is removed and each plant is given the room it requires to flourish.

- Effective Seed Treatment: A delinted seed’s smooth surface enables a consistent layer of protective treatments, providing the highest level of defense against illnesses that are transmitted through seeds and the soil.

Types of Cotton Seed Delinting Plants

1. Acid Delinting Plant

- In this method, sulphuric acid is used to burn off the lint from the seed surface. Though it gives excellent results, this method requires careful handling due to safety and environmental concerns. Padsons provides acid delinting plants with complete safety systems, fume handling units, and corrosion-resistant material.

2. Dry Mechanical Delinting Plant

- This is the most popular method. It uses a mechanical process involving rollers and brushes to scrub off the lint from the seeds. Padsons offers high-capacity dry delinting plants that ensure fast and effective lint removal.

3. Mini Delinting Plant Small Capacity

- For farmers’ groups, small-scale processors, and research institutes, Padsons offers compact and affordable mini delinting units. These plants are ideal for low-volume operations but deliver the same quality of delinting.

4. Automatic Cotton Seed Delinting Plant

- Padsons also manufactures fully automated delinting plants with smart controls and minimal human involvement. These units are best suited for large seed processing units and seed corporations.

3. Semi-Automatic Delinting Plant

- For medium-scale businesses, our semi-automatic models offer a cost-effective yet efficient solution.

4. Fully Automatic Delinting Plant

- These are high-end plants with complete automation and minimal human intervention.

Conclusion

It is impossible to exaggerate how crucial a good cotton seed delinting plant is. Whether it is a vital food ingredient or an article of apparel, it is an essential link in the chain that connects the cotton field to the finished product. Delinting enhances seed quality, which benefits farmers by increasing yields and facilitating more efficient industry operations. We are the best Best Cotton Seed Delinting Plant Manufacturer.

Selecting the best manufacturer of delinting plants is a crucial choice. Padsons Industries is a name you can trust because of our decades of experience, dedication to innovation, and emphasis on customer satisfaction. We are committed to provide cutting-edge equipment that not only satisfies but also beyond industry requirements.