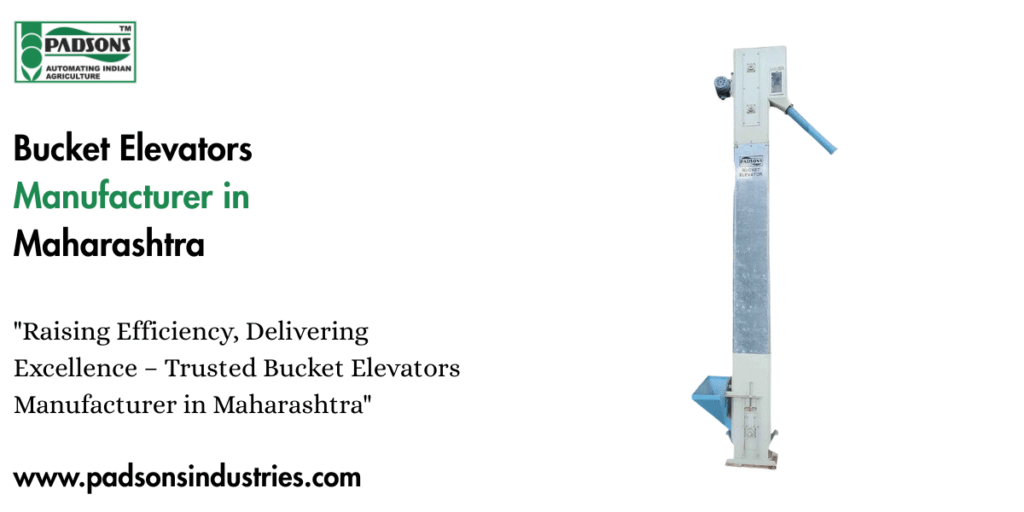

Bucket Elevators Manufacturer in Maharashtra

Introduction

At Padsons Industries, we specialize in crafting user-friendly manual and semi-automatic farm machinery. With a focus on simplicity and effectiveness, our equipment is designed to make farming tasks more efficient and accessible for all. Our range includes a variety of tools that cater to the diverse needs of farmers. From easy-to-use plows to hassle-free seeders, we take pride in creating machinery that simplifies the farming process. With decades of experience in the industry, we understand the challenges faced by modern-day farmers. That’s why we’re dedicated to providing practical solutions that enhance productivity and yield. Trust Padsons Industries to be your reliable partner in agriculture.

Material handling is critical in Maharashtra’s rapidly expanding industrial landscape, guaranteeing smooth operations across all sectors. A bucket elevator is a very efficient and dependable method for vertical material movement. These devices, which hoist bulk items vertically, are widely utilized in industries such as agricultural, food processing, cement, mining, and chemical processing. If you are seeking for a reputable Bucket Elevators Manufacturer in Maharashtra, Padsons Industries stands out as a dependable partner who provides quality, efficiency, and durability. We are the best Bucket Elevators Supplier.

What Are Bucket Elevators

A bucket elevator is a mechanical device designed to convey bulk items upwards. It consists of a series of buckets connected to a belt or chain that rotates around two pulleys or sprockets. The buckets sweep up material from a lower level, transport it up, and discharge it at a higher level. Bucket elevators are extremely effective at transporting grains, powders, pellets, and other granular items. We are the best Bucket Elevators Exporter.

Why Choose Padsons Industries

- Unmatched Build Quality and Durability: At our production facility in Maharashtra, quality is not a step it is the basis. We employ high-quality materials and components. Our fabrication procedures, from cutting to welding, follow tight quality control protocols. The end result is a bucket elevator that can endure the test of time and the rigors of continuous use, reducing your maintenance concerns.

- Deep-Down Customization: We are aware that “off-the-shelf” solutions are rarely effective in industrial settings. We create it from the ground up, whether you require a Continuous Bucket Elevator for delicate or abrasive items or a Centrifugal Discharge Elevator for free-flowing materials. To create an elevator that operates flawlessly in your particular setting, we take into account variables like temperature, moisture content, lump size, and material density.

- Internal Engineering Knowledge: Our employees are our greatest asset. Deep domain knowledge in mechanical and process engineering is possessed by our team of seasoned experts. They innovate to address intricate material handling problems, guaranteeing your operation’s maximum throughput and energy efficiency. They don’t merely adhere to norms.

- Strong and Sturdy Construction Durability is a must in a sector where downtime is costly. We only employ the best materials at our cutting-edge production facilities in Maharashtra. Every part, from the chain’s strength to the buckets’ grade and the steel casing’s thickness, is chosen for optimal durability and strength. The elevator you receive is made to last for decades thanks to our strict quality control at every stage of production.

- Cost-effectiveness and efficiency Our elevators are built to run smoothly and with little electricity usage. We guarantee that your material is pushed with the least amount of energy waste by optimizing the head, boot, and discharge sections. Additionally, over the course of the machine’s lifetime, our robust design lowers the frequency of repairs and part replacements, resulting in noticeably decreased maintenance expenses. Purchasing a Padsons elevator is an investment in future financial gains.

- Innovative and User-Friendly Solutions: Padsons is known for its innovation and has even received patents for its agricultural machinery. Their Bucket Elevators are designed to be user-friendly, with features like manual discharge control systems and level-indication windows, making them easy to operate and maintain.

- Excellent After-Sales Service: For Padsons, Bucket Elevators a product is just the beginning. They are committed to building long-term relationships with their clients and provide prompt and efficient after-sales service. This is a crucial benefit, especially for agricultural and industrial machinery where minimal downtime is essential.

- Customization and Versatility: While they have a range of standard products, Padsons Industries also excels at providing customized solutions. Whether a client needs a specific capacity, a unique dimension, or special features for a particular application, the company’s engineering team can deliver a tailored product that meets their exact requirements.

- Competitive Pricing: Padsons Industries believes in providing world-class products at the most reasonable prices. They have optimized their manufacturing processes to ensure efficiency without compromising on quality, making their storage bins a cost-effective investment in the long run.

Applications of Bucket Elevators

1. Agriculture Industry

- In agriculture, bucket elevators are used to transport grains, seeds, rice, wheat, and pulses from storage areas to processing units. They prevent wastage, reduce manual labor, and enhance productivity.

2. Food Processing Industry

- Food processing plants require hygienic, safe, and efficient material handling. Bucket elevators are used to transport raw ingredients, sugar, flour, and other food products, ensuring smooth processing.

3. Chemical Industry

- In chemical manufacturing, powders, granules, and pellets are commonly handled. Bucket elevators ensure safe and spill-free vertical transport, reducing contamination and production losses.

4. Mining and Mineral Industry

- Mining industries rely on bucket elevators to transport ores, sand, cement, and other minerals. Their robust construction allows them to handle heavy and abrasive materials efficiently.

5. Cement and Construction Industry

- Bucket elevators are widely used in cement plants to lift raw materials, clinker, and finished products. They ensure continuous production without interruptions, boosting operational efficiency.

6. Mining Industry

- In mining operations, bucket elevators are used to lift ores, coal, and other mined materials from lower levels to higher storage or processing units. Padsons Industries’ machines are known for their ruggedness and ability to handle heavy-duty mining applications.

7. Construction Industry

- Construction materials like sand, cement, and aggregates can be transported vertically using bucket elevators, streamlining the construction workflow. The elevators ensure timely delivery of raw materials to the required height, saving time and labor.

Specifications Table of Bucket Elevators

| Parameter | Specification |

|---|---|

| Material | Bucket Elevators |

| Capacity | 2 – 100 Tons/Hour |

| Height | Up to 40 Meters |

| Bucket Material | High-Quality Mild Steel / Stainless Steel |

| Belt/Chain Material | PVC, Rubber, or Steel Chain |

| Motor Power | 3 – 50 HP |

| Discharge Type | Continuous or Centrifugal |

| Suitable Material | Grains, Cement, Fertilizers, Minerals, Chemicals |

| Operation | Automatic / Manual Control |

| Warranty | 1 Year |

Benefit of Bucket Elevators

- Maximized Space Utilization: In crowded industrial plants, floor space is gold. Bucket elevators are designed for vertical movement, taking up a very small footprint while achieving significant lift heights. This frees up valuable floor space for other machinery or storage.

- High Efficiency and Large Capacity: Unlike manual handling or some other conveyor types, bucket elevators can move massive volumes of material continuously and reliably. This ensures a steady, uninterrupted supply to your production line, preventing bottlenecks and maximizing output.

- Gentle Material Handling: For fragile materials like grains or certain chemicals, a gentle touch is needed. Modern bucket elevators can be designed for minimal impact during loading and gentle discharge, preserving the quality and integrity of your product and reducing breakage or degradation.

- Low Power Consumption: Compared to the energy required for front-end loaders or other complex systems, a well-engineered bucket elevator is a highly energy-efficient way to move material vertically. This translates directly to lower operational costs.

- Durability and Low Maintenance: Built with robust materials and simple principles, a good bucket elevator is a long-term asset. With minimal moving parts in direct contact with the material, they require less maintenance and offer a long service life, providing an excellent return on investment.

- Versatility Across Industries: The true power of a bucket elevator lies in its adaptability. They are used across a vast spectrum of industries, which is why having a manufacturer who understands these nuances is critical.

- Efficiency and High Capacity: Bucket elevators can move large volumes of material quickly and continuously. This eliminates bottlenecks and keeps your production throughput high.

- Space-Saving Design: Their vertical footprint means they take up very little floor space. This is a huge advantage in facilities where space is at a premium, allowing for a more optimized layout.

- Gentle Material Handling: Modern bucket elevators are designed to handle materials with care. With the right bucket and belt/chain combination, they can move fragile products without causing damage or degradation.

- Dust-Free and Enclosed Operation: A well-built elevator is fully enclosed. This containment is crucial for preventing dust from escaping into the atmosphere, which is vital for both worker safety and environmental compliance.

- Low Power Consumption: Compared to the cost of manual labor or other complex mechanical systems, bucket elevators are remarkably energy-efficient, leading to lower operational costs.

Types of Bucket Elevators

1. Centrifugal Discharge Bucket Elevator

- This type of bucket elevator uses centrifugal force to throw materials out of the bucket at high speed. It is commonly used for free-flowing materials like grains, seeds, and fertilizers. The centrifugal discharge bucket elevator is ideal for industries requiring fast and efficient vertical material handling.

2. Continuous Discharge Bucket Elevator

- Continuous discharge bucket elevators are designed to handle fragile or sticky materials that cannot be thrown out by centrifugal force. The buckets are positioned in such a way that the material is discharged smoothly as the bucket moves over the head pulley. This type is perfect for chemical powders, food products, and other sensitive materials.

3. Positive Discharge Bucket Elevator

- Positive discharge bucket elevators ensure that all materials are discharged completely without leaving residues. They are suitable for heavy, abrasive, or sticky materials that require precise handling. Industries such as cement plants and mineral processing units often prefer this type.

4. Belt Bucket Elevator

- Belt bucket elevators use a belt to carry the buckets. They are cost-effective, require low maintenance, and are widely used in agriculture and food processing industries.

5. Chain Bucket Elevator

- Chain bucket elevators are ideal for handling very heavy or hot materials. They use a chain instead of a belt, which makes them more durable and capable of handling harsh operating conditions.

Conclusion

Productivity in today’s cutthroat industrial environment depends on effective material handling. When it comes to vertical bulk material transportation, bucket elevators are essential, and selecting the correct manufacturer guarantees long-term advantages. We are the Best Bucket Elevators Manufacturer.

Padsons Industries, a top producer of bucket elevators in Maharashtra, offers dependable solutions to industries by fusing quality, experience, and customization. Padsons Industries guarantees that customers receive equipment that improves productivity and lowers operating expenses from design to installation and maintenance.