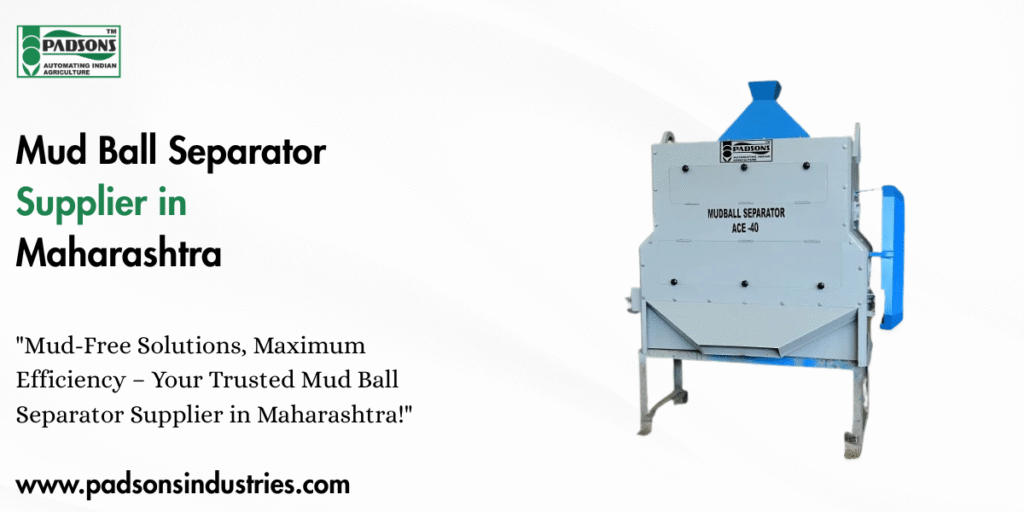

Mud Ball Separator Supplier in Maharashtra

Introduction

At Padsons Industries, we specialize in crafting user-friendly manual and semi-automatic farm machinery. With a focus on simplicity and effectiveness, our equipment is designed to make farming tasks more efficient and accessible for all. Our range includes a variety of tools that cater to the diverse needs of farmers. From easy-to-use plows to hassle-free seeders, we take pride in creating machinery that simplifies the farming process. With decades of experience in the industry, we understand the challenges faced by modern-day farmers. That’s why we’re dedicated to providing practical solutions that enhance productivity and yield. Trust Padsons Industries to be your reliable partner in agriculture.

High-quality sand is crucial for building long-lasting structures in the industrial and construction sectors. However, mud balls, lumps of clay, and other undesirable particles are frequently found in natural sand. These contaminants have the potential to degrade building materials and affect the overall quality of the project. In this situation, a mud ball separator is essential for helping businesses easily obtain clean, high-quality sand.Padsons Industries stands out as a reputable and knowledgeable supplier if you’re looking for a mud ball separator in Maharashtra. They sell high-quality equipment made to increase the effectiveness of sand processing. We are the best Mud Ball Separator Manufacturer.

What is a Mud Ball Separator

A specialized device called a mud ball separator is used to separate clay lumps, mud balls, and other contaminants from sand. It guarantees that the sand is pure, devoid of undesirable materials, and appropriate for usage in industrial and construction settings. The machine operates on a straightforward principle: water and sand are fed into the separator, where a screw system or revolving drum lifts and separates the mud balls from the sand. After that, the clean sand is gathered and made usable. We are the best Best Mud Ball Separator Supplier.

Why Choose Padsons Industries

- Uncompromising Build Quality: Our mud ball separators are built to last. We use high-grade, abrasion-resistant materials in critical components to ensure the machine can handle the toughest filter media day in and day out, year after year. This reduces long-term maintenance costs and extends the machine’s lifecycle, giving you a superior return on your investment.

- Proven and Efficient Design: The effectiveness of a separator lies in its design. Our engineers have perfected the internal geometry and tumbling action to ensure maximum mud ball breakup with minimal wear on the valuable filter media itself. You get clean, reusable media that performs like new, protecting your core filtration process.

- Customized for Your Needs: We understand that a power plant in Chandrapur has different needs than a textile unit in Ichalkaranji or a water treatment facility in Aurangabad. That’s why we don’t believe in a one-size-fits-all approach. We offer customized solutions tailored to your specific media type, plant capacity, and operational requirements.

- End-to-End Service Support: Our relationship doesn’t end with a sales receipt. As a Maharashtra-based company, we provide comprehensive support, from site evaluation and installation guidance to operational training and prompt after-sales service. Our technical team is always on standby to ensure your operations run smoothly.

- A Reputation Built on Trust: Our greatest asset is the trust of our customers. Our growing list of repeat clients across Maharashtra is a testament to our commitment to quality and service. When you choose Padsons, you are choosing a partner who is invested in your success.

- Customization to Fit Your Plant: We understand that every plant has a unique setup and capacity requirement. A standard, off-the-shelf solution rarely works perfectly. Padsons Industries prides itself on offering customized solutions. Whether you need a specific size, a different power configuration, or a unique material compatibility, our engineering team works with you to design a mud ball separator that integrates seamlessly into your existing system.

- Proven Expertise and Industry Experience: Our journey has given us deep insights into the challenges faced by various sectors—be it municipalities, power plants, steel plants, or the chemical industry. This experience is baked into every product we design. When you partner with us, you are leveraging years of practical, on-ground expertise.

- Reliable After-Sales Support: Our relationship with you doesn’t end with a sale. We see it as the beginning. As a responsible Mud Ball Separator Supplier in Maharashtra, we have a dedicated service team ready to assist you with installation guidance, routine maintenance tips, and prompt supply of spare parts. We ensure your operations run smoothly, with minimal downtime.

- Cost-Effectiveness in the True Sense: While our initial price point is highly competitive, our real value lies in the Total Cost of Ownership. A Padsson separator, with its durability and efficiency, saves you money every single day through lower energy bills, reduced water wastage, decreased maintenance costs, and avoiding costly production stoppages. It’s an investment that pays for itself.

Applications of Mud Ball Separators

1. Rice Mills

- In rice processing, removing stones, mud balls, and other heavy particles is crucial to prevent damage to milling machines. Padsons Mud Ball Separators efficiently clean paddy, ensuring higher yield and premium-quality rice.

2. Wheat Processing Units

- Wheat grains often carry stones, mud, and other foreign materials. Mud Ball Separators help maintain grain purity, improving flour quality and reducing equipment wear in mills.

3. Seed Processing

- Seed industries rely on pure seeds for better germination. Padsons Mud Ball Separators remove mud balls and stones, enhancing seed quality and promoting healthy crop growth.

4. Pulses and Legumes Processing

- Pulses like lentils, chickpeas, and beans often contain stones and mud. Efficient separation ensures cleaner products, reduces wastage, and meets export quality standards.

5. Food Processing Industries

- In large-scale food processing units, contaminants can damage machinery and compromise food safety. Mud Ball Separators ensure smooth production and consistent product quality.

6. Agriculture and Grain Processing

- In agriculture, mud balls, stones, and other impurities in grains such as rice, wheat, and pulses can cause processing issues. Mud Ball Separators help in cleaning the grains before they are milled or packaged, improving product quality and shelf life.

7. Mineral and Mining Industry

- In mineral processing, mud balls or clay lumps can interfere with the extraction and refinement processes. Separators efficiently remove these impurities, ensuring smoother operations and higher yield.

8. Chemical and Pharmaceutical Industries

- Uniformity of raw materials is critical in chemical and pharmaceutical production. Mud Ball Separators ensure that powders and granular materials are free from lumps, providing consistency in production.

Table of Specifications Mud Ball Separators

| Feature | Specification |

|---|---|

| Material | Mud Ball Separator |

| Material | High-grade stainless steel / Mild steel |

| Capacity | 1-5 tons per hour (customizable based on requirement) |

| Motor Power | 1.5 – 5 HP |

| Power Supply | 220V / 380V, 50 Hz |

| Efficiency | Up to 99% separation of mud balls and impurities |

| Maintenance | Low maintenance, easy to clean |

| Applications | Rice, grains, pulses, and other agricultural products |

| Delivery | Maharashtra (Mumbai, Pune, Nagpur, Nashik, Aurangabad) |

| Warranty | 12 months manufacturer warranty |

Advantage of Mud Ball Separators

- Protects Your Expensive Equipment: Downstream from your intake point, you likely have pumps, valves, heat exchangers, and other sensitive equipment. Abrasive particles like sand act like sandpaper, causing rapid wear and tear, leading to frequent breakdowns and costly repairs. A separator acts as the first line of defense.

- Improves Final Product Quality: Whether you are producing purified water, chemicals, or food and beverage products, purity is paramount. Contaminants can compromise your entire batch, leading to rejections and lost revenue. A separator ensures a cleaner starting point.

- Reduces Maintenance Downtime: Clogged filters, damaged pump impellers, and scaled-up systems mean one thing: downtime. By removing the abrasive particles at the source, you significantly reduce the frequency of maintenance, keeping your production line running smoothly and profitably.

- Enhances Overall System Efficiency: Cleaner systems operate more efficiently. Your pumps use less energy, your filters last longer, and your heat exchangers transfer heat better. This leads to direct savings on your power bills.

- Safeguards Ion Exchange Resins: In water softening and demineralization plants, resin beads are the heart of the process. Mud balls and broken resins can foul the entire bed, reducing its capacity and requiring premature replacement—a very expensive affair. A mud ball separator effectively filters these out.

- Customization to Fit Your Needs: We understand that every plant is unique. Whether you need a specific inlet outlet size, a special material of construction, or a unique capacity, our engineering team can customize the mud ball separator to fit your exact process requirements.

- Cost-Effective and Long-Lasting: Investing in a Padsons Industries separator is a cost-effective decision in the long run. By preventing equipment damage and reducing maintenance, our separators pay for themselves many times over. Their durability means you won’t be facing replacement costs anytime soon.

- Expert Technical Support: Our team doesn’t just take your order; we understand your application. We provide expert advice to help you select the right model and offer continuous support for installation and operation.

- Restores Filtration Efficiency: By removing mud balls, the filter bed regains its uniform porosity. This means water passes through evenly, resulting in crystal-clear, high-quality output water that meets compliance standards.

- Slashes Operational Costs: Every time you backwash a clogged filter, you’re wasting water and energy. With a separator, the interval between backwashes increases significantly. This leads to direct savings on water and electricity bills. You also drastically reduce the need for frequent, expensive media replacement.

- Boosts Plant Capacity & Uptime: A clean filter media works faster and more effectively. This can increase the overall throughput of your treatment plant. Less downtime for manual cleaning or media changeouts means more productive uptime for your core operations.

Types of Mud Ball Separators

1. Manual Mud Ball Separators

- Manual separators are simple machines that require human operation to remove mud balls from slurry or sand. These are cost-effective and suitable for small-scale operations. Key features include:

2. Automatic Mud Ball Separators

- Automatic mud ball separators are designed for large-scale industrial operations. They use mechanical or hydraulic systems to remove mud balls continuously without manual intervention. Benefits include.

3. Rotary Mud Ball Separators

- Rotary separators use rotating drums or cylinders to separate mud balls from slurry. The rotation helps to break up mud balls and ensures smooth processing. Features:

4. Vibratory Mud Ball Separators

- Vibratory separators use vibration to shake off mud balls and other unwanted particles. They are highly effective for fine materials and sand processing. Advantages:

5. Customized Industrial Separators

- For specialized operations, Padsons Industries also offers customized mud ball separators. These machines are designed based on project-specific requirements, including capacity, material type, and operational environment.

Conclusion

A mud ball separator is an essential component of industrial processes where efficiency and quality are crucial. Padsons enterprises is the preferred Mud Ball Separator Supplier for Maharashtra enterprises looking for dependable, high-performing, and reasonably priced solutions.

Our dedication to technology, quality, and client pleasure guarantees that companies may minimize operational difficulties while maintaining high production standards. When you work with Padsons Industries, you invest in long-term performance, dependability, and durability rather than merely buying a machine.